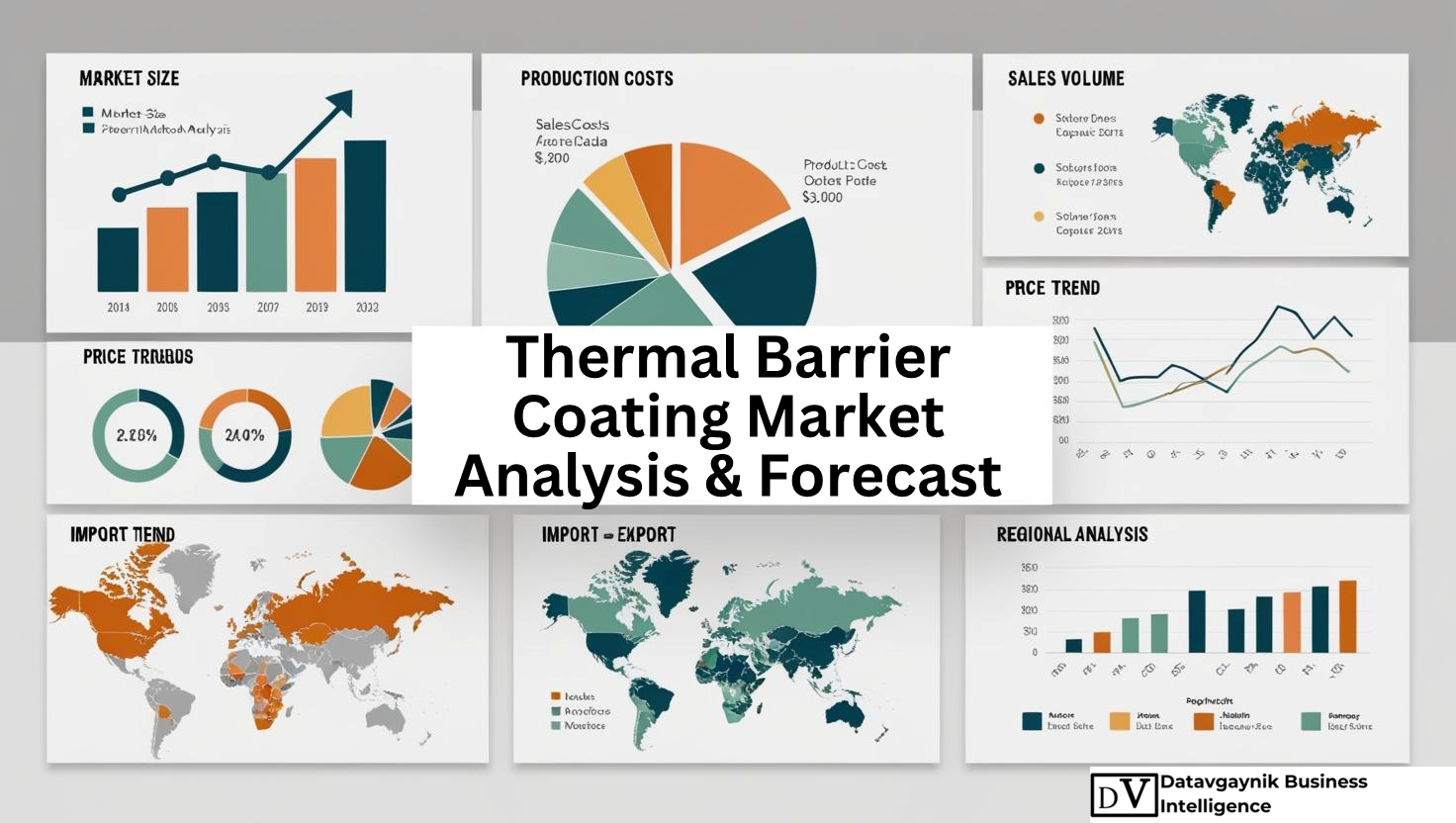

Thermal Barrier Coating Market Size, Production, Sales, Average Product Price, Market Share, Import vs Export

- Published 2025

- No of Pages: 120+

- 20% Customization available

Global Dynamics Shaping the Thermal Barrier Coating Market

The Thermal Barrier Coating Market is experiencing rapid momentum due to the rising demand for advanced heat-resistant materials across multiple high-temperature applications. For instance, in the aerospace sector, turbine inlet temperatures in modern jet engines now exceed 1500°C, necessitating the use of thermal barrier coatings to prevent material degradation and enhance efficiency. As global aircraft production is expected to cross 46,000 new deliveries by 2042, with a major share led by narrow-body aircraft, the demand for thermal protection solutions such as TBCs continues to surge, positioning the Thermal Barrier Coating Market for accelerated growth.

The Thermal Barrier Coating Market is experiencing rapid momentum due to the rising demand for advanced heat-resistant materials across multiple high-temperature applications. For instance, in the aerospace sector, turbine inlet temperatures in modern jet engines now exceed 1500°C, necessitating the use of thermal barrier coatings to prevent material degradation and enhance efficiency. As global aircraft production is expected to cross 46,000 new deliveries by 2042, with a major share led by narrow-body aircraft, the demand for thermal protection solutions such as TBCs continues to surge, positioning the Thermal Barrier Coating Market for accelerated growth.

Aerospace Expansion Accelerating Thermal Barrier Coating Market

One of the primary growth drivers for the Thermal Barrier Coating Market is the continuous expansion of the aerospace industry. Jet engine manufacturers are increasingly focusing on improving fuel efficiency, reducing emissions, and extending engine lifespan—goals directly tied to the adoption of high-performance coatings. For example, Rolls-Royce’s UltraFan engine, designed for 25% improved fuel efficiency, relies on advanced ceramic thermal barrier coatings to withstand higher operating temperatures. Similarly, Pratt & Whitney and GE Aviation have incorporated multi-layered TBC systems to handle extreme heat flux in next-gen turbine engines. These developments reflect a tangible shift in aerospace engineering, and with the global aerospace industry projected to grow at a CAGR of over 7% through 2030, the Thermal Barrier Coating Market is poised to benefit significantly.

Datavagyanik also covers related markets such as the Thermal Cured Hydrophilic Coating Market. Understanding these markets sheds light on emerging innovations and industry crossovers that impact the main topic.

Thermal Barrier Coating Market Driven by Gas Turbine Expansion in Power Sector

The evolution of gas turbine technology in power generation is another factor catalyzing the Thermal Barrier Coating Market. Gas turbines used in combined-cycle plants now operate at firing temperatures surpassing 1600°C. To maintain mechanical integrity under these severe thermal conditions, turbine blades and components are increasingly coated with ceramic-based TBCs. For instance, General Electric’s HA-class gas turbines—considered the most efficient in the world—use multiple thermal barrier layers to ensure sustained performance over long operational lifespans. With global energy demand forecasted to increase by over 25% by 2040, and a sizable share coming from gas-fired plants, thermal protection technology is a critical enabler, boosting investment and innovation within the Thermal Barrier Coating Market.

Automotive Innovations Fueling Thermal Barrier Coating Market Adoption

In the automotive sector, particularly among performance and electric vehicles, the Thermal Barrier Coating Market is witnessing significant traction. Manufacturers such as BMW, Ferrari, and Tesla are utilizing thermal barrier coatings in exhaust manifolds, turbochargers, and battery enclosures to manage heat dissipation and improve powertrain durability. For example, Porsche’s high-performance engines feature plasma-sprayed ceramic coatings to reduce thermal fatigue and enhance combustion efficiency. With global EV production projected to exceed 40 million units annually by 2030, thermal management becomes a key design parameter. As battery packs generate heat during rapid discharge, advanced coatings that provide both insulation and thermal protection are being widely adopted—further reinforcing the growth of the Thermal Barrier Coating Market.

Material Science Advancements Boosting the Thermal Barrier Coating Market

Technological progress in material science has led to the development of highly resilient ceramic and composite coatings, directly impacting the capabilities of the Thermal Barrier Coating Market. Yttria-stabilized zirconia (YSZ), for instance, remains the gold standard due to its low thermal conductivity and high phase stability. However, newer multi-layered systems incorporating gadolinium zirconate, rare earth aluminate, and other advanced compounds are extending operating temperature thresholds beyond 1700°C. These materials are not only enhancing performance in aerospace and industrial turbines but are also finding applications in nuclear power systems and defense-grade propulsion. The shift from single-layer to multi-layer and functionally graded coatings represents a strategic evolution in the Thermal Barrier Coating Market, reflecting demand for increased thermal efficiency and reliability.

Surge in Renewable Energy Driving the Thermal Barrier Coating Market

The push toward decarbonization and cleaner energy sources has also opened new avenues for the Thermal Barrier Coating Market. Concentrated solar power (CSP) systems, which operate by converting sunlight into heat for power generation, require materials that can endure prolonged exposure to extremely high temperatures. For instance, molten salt receivers in CSP plants must function efficiently above 600°C, necessitating the use of ceramic-based TBCs. Countries such as Spain, Morocco, and the UAE, which have ramped up CSP installations, are increasingly investing in TBC technologies to improve the durability and thermal performance of their solar infrastructures. As global renewable energy capacity is projected to increase by over 2,400 GW between 2024 and 2030, the role of thermal coatings in improving energy efficiency is becoming more critical, strengthening the long-term outlook of the Thermal Barrier Coating Market.

Thermal Barrier Coating Market Growth Supported by Industrial Manufacturing Needs

Industrial manufacturing sectors, particularly those involving metal processing, cement production, and chemical refining, are key contributors to the growth of the Thermal Barrier Coating Market. High-temperature furnaces, kilns, and reactors require consistent thermal insulation to optimize fuel use and reduce component degradation. For example, in steel production, ladle and tundish systems are coated with TBCs to prevent heat loss and protect structural components. As industrial energy efficiency becomes a major focus globally, and with global furnace technology projected to witness a CAGR of over 5%, the reliance on high-performance thermal coatings is set to increase. The Thermal Barrier Coating Market stands to benefit from these broader industry transitions aimed at minimizing operational losses and maximizing throughput.

Electric Mobility Creating Fresh Demand for the Thermal Barrier Coating Market

The global transition toward electric mobility is creating new thermal management challenges, directly impacting the trajectory of the Thermal Barrier Coating Market. Electric vehicle battery modules generate significant amounts of heat during operation and fast-charging cycles, making temperature regulation essential for safety and efficiency. OEMs such as Lucid Motors and Rivian have begun integrating advanced thermal barrier coatings within battery casings and thermal interface materials to mitigate overheating risks. Additionally, solid-state battery development—which involves higher energy densities—requires even more robust thermal protection systems. With EV battery demand expected to grow at over 30% CAGR through 2030, thermal barrier coating production will continue to expand, with new use cases emerging in battery systems, inverters, and charging equipment.

Defense and Space Applications Catalyzing the Thermal Barrier Coating Market

The Thermal Barrier Coating Market is also significantly influenced by investments in defense and space technologies. Hypersonic vehicles, space propulsion systems, and military jet engines function in extremely hostile environments where surface temperatures can exceed 2000°C. Thermal barrier coatings in such applications must not only resist extreme heat but also survive mechanical stress and rapid thermal cycling. For example, NASA and the U.S. Department of Defense have funded the development of ultra-high-temperature ceramics (UHTCs) and nano-structured coatings to meet next-generation aerospace requirements. These innovations are being commercialized for civil aerospace and energy sectors as well, further embedding advanced thermal barrier solutions into global value chains and driving the long-term growth of the Thermal Barrier Coating Market.

Environmental Regulations and Energy Efficiency Targets Supporting the Thermal Barrier Coating Market

Governments and regulatory bodies around the world are enforcing stricter emission and energy efficiency standards across industrial and transportation sectors. For instance, the European Union’s Industrial Emissions Directive and the U.S. Department of Energy’s Advanced Manufacturing Office initiatives have emphasized the adoption of heat-reducing technologies in manufacturing. These measures directly encourage the application of thermal barrier coatings to reduce energy consumption and emissions. Moreover, the push to meet carbon neutrality goals by 2050 is compelling industries to deploy energy-saving solutions. Thermal barrier coatings, with their proven ability to enhance thermal efficiency and extend component lifecycles, are increasingly being seen as critical enablers in this transformation, reinforcing their indispensable role in the Thermal Barrier Coating Market.

“Track Country-wise Thermal Barrier Coating Production and Demand through our Thermal Barrier Coating Production Database”

-

-

- Thermal Barrier Coating production database for 20+ countries worldwide

- Country-wise Thermal Barrier Coating production capacity and production plant mapping

- Thermal Barrier Coating production plants and production plant capacity analysis for key manufacturers

-

North America Leading Thermal Barrier Coating Market with Aerospace and Defense Investment

The Thermal Barrier Coating Market in North America continues to lead in innovation and production, with the United States accounting for a significant share of global consumption and exports. For example, the presence of aerospace giants such as Lockheed Martin, Boeing, and Raytheon Technologies has solidified the region’s reliance on thermal protection systems. Advanced jet engines, particularly for military aircraft, operate in excess of 1600°C, and require high-performance TBCs for turbine blades and afterburner systems. The U.S. government has earmarked billions in defense modernization, which includes thermal coating research programs. This consistent flow of funding supports a strong domestic supply chain and bolsters the growth of the Thermal Barrier Coating Market in the region.

In addition, North America’s focus on gas-fired power generation continues to drive the application of TBCs in industrial turbines. General Electric’s HA-class turbines, known for their record-breaking efficiency levels of up to 64% in combined-cycle mode, rely heavily on ceramic thermal barrier coatings. These high-output turbines are increasingly deployed in energy infrastructure projects across the U.S., Canada, and Mexico, reinforcing North America’s stronghold in the Thermal Barrier Coating Market.

Europe Thermal Barrier Coating Market Expands with Automotive and Sustainable Energy Applications

The Thermal Barrier Coating Market in Europe is experiencing rapid transformation as the region balances industrial performance with environmental regulations. For instance, Germany’s automotive sector, home to brands like BMW, Audi, and Porsche, has been leveraging TBCs in high-performance engines and turbochargers. These coatings significantly reduce component wear, improve combustion efficiency, and lower emissions, aligning with the EU’s stringent CO₂ reduction targets. As Europe prepares for the 2035 ban on internal combustion engine vehicle sales, thermal barrier coatings are being repurposed for EV thermal management systems, highlighting their evolving relevance.

France and the United Kingdom have also played pivotal roles in aerospace-oriented coating technologies. France, with Airbus and Safran, is investing heavily in new engine programs such as the RISE (Revolutionary Innovation for Sustainable Engines), which integrates ceramic matrix composites and TBCs to withstand higher temperatures. Meanwhile, the UK’s Rolls-Royce is advancing its UltraFan engine series, requiring coatings that can operate reliably at peak thermal loads. Across Europe, gas turbines supporting renewable energy projects, such as waste-to-energy and combined heat and power systems, are also increasing their reliance on thermal barrier coating systems, further expanding the market footprint.

Asia-Pacific Emerging as Thermal Barrier Coating Market Manufacturing Powerhouse

Asia-Pacific is emerging as a manufacturing and consumption hub within the Thermal Barrier Coating Market, led by countries like China, Japan, and South Korea. China’s aerospace sector, for example, has been scaling rapidly with programs like COMAC’s C919 passenger aircraft, which employs Western and local engine technologies demanding thermal protection solutions. Additionally, China’s energy infrastructure, including over 1000 GW of coal and gas-fired capacity, creates sustained demand for TBCs to ensure turbine efficiency and lifespan.

Japan is known for its material science leadership, and this directly benefits the development of advanced TBC formulations. The country’s automotive industry—anchored by Toyota, Honda, and Nissan—uses thermal barrier coatings extensively in turbocharged engines and emerging solid-state EV battery systems. South Korea, on the other hand, integrates thermal coatings into both defense aviation systems and semiconductor cooling solutions. For example, TBCs are used in high-performance heat sinks and thermal interface layers within chip fabrication tools, adding an entirely new vertical to the Thermal Barrier Coating Market in the region.

India and Southeast Asia Creating New Frontiers in Thermal Barrier Coating Market

India’s Thermal Barrier Coating Market is growing rapidly, fueled by the government’s push for domestic defense manufacturing under the “Make in India” initiative. For instance, the Tejas fighter jet program and gas turbine overhaul initiatives in power plants are generating significant local demand for TBC technologies. Additionally, India’s automotive and industrial furnace sectors are integrating coatings to improve thermal efficiency and reduce operational costs. With nearly 60% of India’s electricity still generated from thermal sources, thermal barrier coatings are vital to upgrading power plant efficiency metrics.

Southeast Asian countries like Thailand, Vietnam, and Indonesia are also stepping up their use of TBCs, especially in petrochemical refining, steel manufacturing, and gas-fired generation. These regions are increasingly sourcing TBCs through joint ventures with global producers, and many governments are offering incentives to establish local coating application units. The increasing industrial base and regional shift toward energy efficiency policies are making Southeast Asia an emerging growth pocket in the global Thermal Barrier Coating Market.

Middle East and Africa Expanding Thermal Barrier Coating Market through Energy Sector Investments

The Thermal Barrier Coating Market in the Middle East and Africa is benefiting from large-scale investments in power generation and petrochemical processing. For example, Saudi Arabia’s Vision 2030 includes diversification into high-efficiency gas turbine-based power projects, many of which utilize GE and Siemens turbine systems that rely on TBCs for high-temperature performance. Similarly, UAE’s growing renewable energy sector, especially concentrated solar power plants like Noor Energy 1, demands thermal coatings to protect high-temperature receivers.

In Africa, thermal barrier coatings are being adopted in mining equipment and cement kilns, where extreme temperatures and mechanical abrasion require robust surface protection. South Africa’s Sasol, for instance, uses advanced coating solutions in its synthetic fuel plants. These use cases indicate a widening adoption curve for TBCs in regions historically underserved, signaling new growth avenues for the global Thermal Barrier Coating Market.

“Thermal Barrier Coating Manufacturing Database, Thermal Barrier Coating Manufacturing Capacity”

-

-

- Thermal Barrier Coating top manufacturers market share

- Top five manufacturers and top 10 manufacturers of Thermal Barrier Coating in North America, Europe, Asia Pacific

- Production plant capacity by manufacturers and Thermal Barrier Coating production data for market players

- Thermal Barrier Coating production dashboard, Thermal Barrier Coating production data in excel format

-

Segment Analysis by Product Type in the Thermal Barrier Coating Market

In terms of product segmentation, the Thermal Barrier Coating Market is primarily divided into ceramic-based, metal-based, and intermetallic coatings. Ceramic coatings—especially those based on yttria-stabilized zirconia (YSZ)—hold the largest market share due to their superior heat resistance and phase stability. These are widely applied in aerospace, energy, and automotive components. Metal-based coatings, such as MCrAlY (where M stands for nickel or cobalt), offer excellent oxidation resistance and are often used as bond coats underneath ceramics. Intermetallic coatings, combining metal and ceramic properties, are gaining popularity in niche applications where structural strength and thermal protection are equally critical, such as in defense propulsion systems.

Material Type Drives Functional Performance in Thermal Barrier Coating Market

Material selection in the Thermal Barrier Coating Market plays a decisive role in determining operational outcomes. Yttria-stabilized zirconia remains dominant due to its low thermal conductivity and high durability. For instance, coatings with 7-8% YSZ content are now considered industry-standard for turbine blade applications. Alternatives such as gadolinium zirconate and lanthanum zirconate are gaining attention for applications requiring resistance to CMAS (calcium–magnesium–alumino–silicate) attack, particularly in desert-operating environments.

Other notable materials include aluminum oxide, known for oxidation resistance, and cerium oxide, which is used in environmentally sensitive applications. Mullite coatings, offering structural integrity and thermal resistance, are increasingly being used in industrial furnaces and kilns. The ongoing material innovations are enabling customized solutions across a broader range of applications, accelerating adoption across verticals within the Thermal Barrier Coating Market.

Technology-Based Segmentation in the Thermal Barrier Coating Market

The Thermal Barrier Coating Market is also shaped by the technology used for coating application. Air Plasma Spray (APS) remains the most commonly employed method due to its cost-effectiveness and widespread availability. It is extensively used for turbine blades, combustor parts, and exhaust systems. For higher-performance requirements, Electron Beam Physical Vapor Deposition (EB-PVD) offers better coating uniformity and adhesion, making it ideal for aviation turbines operating at the highest thermal thresholds.

High-Velocity Oxy-Fuel (HVOF) coatings are becoming increasingly relevant in the automotive and industrial sectors due to their high bond strength and lower porosity. Additionally, Chemical Vapor Deposition (CVD) is used for ultra-thin, high-precision coatings, especially in electronics and specialized aerospace components. Each of these technologies addresses different performance parameters and cost constraints, offering diverse solutions that widen the application spectrum of the Thermal Barrier Coating Market.

Thermal Barrier Coating Market Segmentation by Application

The application landscape of the Thermal Barrier Coating Market is led by aerospace, followed by power generation, automotive, and industrial manufacturing. In aerospace, TBCs are critical in turbine blades, nozzles, and afterburners, directly influencing fuel burn rates and component longevity. In power generation, coatings are applied to hot gas path components in combined-cycle plants to improve thermal efficiency and reduce downtime.

In the automotive domain, applications include turbochargers, exhaust manifolds, and pistons in performance engines. As vehicle electrification rises, new use cases in battery thermal shielding and inverter cooling are gaining prominence. Industrial applications include coating furnaces, heat exchangers, and reactor linings, particularly in metal processing and glass manufacturing. This broadening of end-use scenarios is contributing to the sustained growth trajectory of the global Thermal Barrier Coating Market.

“Thermal Barrier Coating Production Data and Thermal Barrier Coating Production Trend, Thermal Barrier Coating Production Database and forecast”

-

-

- Thermal Barrier Coating production database for historical years, 10 years historical data

- Thermal Barrier Coating production data and forecast for next 7 years

-

Major Manufacturers Dominating the Thermal Barrier Coating Market

The Thermal Barrier Coating Market is shaped by a core group of global manufacturers known for advanced coating technologies, material science leadership, and deep integration with aerospace, power generation, automotive, and industrial manufacturing sectors. These companies continue to invest in research and product innovation, pushing the limits of heat resistance, durability, and performance in extreme environments.

Praxair Surface Technologies (a Linde Company)

Praxair Surface Technologies stands as a global leader in the Thermal Barrier Coating Market, especially with its wide-ranging coating solutions tailored for aerospace and energy applications. The company’s ThermaCoat™ and Tafa™ arc spray systems are widely deployed in turbine components, combustion chambers, and high-velocity zones within jet engines. The company offers a comprehensive portfolio that includes air plasma spray (APS), high-velocity oxy-fuel (HVOF), and electron beam physical vapor deposition (EB-PVD) technologies. Praxair’s close partnerships with engine OEMs such as GE and Rolls-Royce further strengthen its strategic position in the market.

Oerlikon Metco

Oerlikon Metco, a key player in the Thermal Barrier Coating Market, offers advanced materials and coating equipment across various industries. Their flagship thermal barrier coating products include Metco 204NS-G, a zirconia-based coating with high thermal shock resistance, and Amdry™ 375, a high-temperature bond coat. Oerlikon also provides coating systems such as TriplexPro™ and MultiCoat™, designed for industrial gas turbines and aerospace turbine engines. The company has heavily invested in nanostructured TBC solutions and additive manufacturing integration to meet the growing performance requirements of modern jet propulsion systems.

Bodycote plc

UK-based Bodycote provides thermal barrier coatings through its Specialist Technologies division, which includes Thermal Spray Coatings, Engineered Coatings, and HIP (Hot Isostatic Pressing) solutions. Bodycote’s services are particularly in demand in aerospace and energy sectors where advanced coating systems are required for turbine components and engine blades. The company’s APS and HVOF coating systems offer resistance to oxidation and corrosion at elevated temperatures. With global processing centers, Bodycote ensures localized service delivery, supporting the growing decentralization trend in the Thermal Barrier Coating Market.

A&A Coatings

A&A Coatings specializes in thermal spray coatings and has become a recognized provider in the Thermal Barrier Coating Market for industrial and aerospace applications. Their A&A YSZ Ceramic Coating is widely applied in high-heat environments such as turbine blades, exhaust systems, and combustion liners. The company also offers A&A Chromium Carbide and Aluminum Oxide-based coatings tailored for wear and oxidation resistance. Known for customized solutions, A&A Coatings has become a go-to partner for smaller OEMs seeking performance optimization in thermal environments.

H.C. Starck Solutions

H.C. Starck, now part of the JX Nippon Mining & Metals group, is a key materials supplier within the Thermal Barrier Coating Market, particularly for ceramic powders and advanced materials. The company produces high-purity yttria-stabilized zirconia, hafnia, and rare earth-based oxides, which are essential in the manufacture of next-generation TBCs. These materials are supplied to major aerospace coating providers and turbine OEMs globally. H.C. Starck’s focus on powder innovation and consistent quality control supports the performance stability demanded in aviation and power sectors.

Sulzer Metco (now integrated into Oerlikon Metco)

Before being fully acquired by Oerlikon, Sulzer Metco had established a strong global presence in the Thermal Barrier Coating Market. Its product range, including ZrO₂-Y₂O₃ thermal spray powders and bond coat powders like NiCoCrAlY, is still marketed under the Oerlikon umbrella. These legacy technologies remain benchmarks in gas turbine TBC systems worldwide. Sulzer Metco’s coating equipment also laid the foundation for Oerlikon’s current suite of automated spray systems and robotic TBC application tools used in high-throughput turbine blade manufacturing.

APS Materials, Inc.

APS Materials is a prominent U.S.-based TBC manufacturer, known for developing custom thermal barrier coatings for aerospace, medical devices, and defense applications. The company uses plasma spray and HVOF processes and offers zirconia-based coatings for turbine blades, combustion liners, and aerospace thruster systems. APS is also involved in developing coatings for next-generation space propulsion technologies, strengthening its position in high-performance niches within the Thermal Barrier Coating Market.

Zircotec Ltd.

Zircotec, a UK-based company, provides advanced ceramic coatings for motorsports, performance automotive, and defense applications. Its product line includes ThermaLight™, a ceramic-based thermal barrier coating applied to exhaust manifolds and engine bay components to manage under-hood temperatures. Zircotec’s plasma-sprayed coatings are popular in Formula 1, rallying, and endurance racing, where extreme heat conditions demand cutting-edge TBCs. As thermal management becomes crucial in electric vehicle battery compartments, Zircotec is actively expanding its application base into EV platforms.

Thermion Inc.

Specializing in arc spray systems, Thermion has carved a niche in industrial applications of thermal barrier coatings. Their Twin Wire Arc Spray (TWAS) systems are utilized in manufacturing heavy machinery and turbine components, where thermal fatigue and oxidation are major concerns. Thermion’s technology is designed for cost-efficient, large-area TBC application, making it valuable for cement, petrochemical, and waste-to-energy sectors. The company supports a growing demand for scalable thermal barrier solutions in emerging infrastructure markets.

Progressive Surface Inc.

Progressive Surface is a global leader in surface finishing and thermal spray automation, providing integrated solutions for thermal barrier coating application. The company’s custom-engineered plasma spray cells are widely used by aerospace manufacturers for high-precision coating of turbine components. Their clients include GE Aviation, Pratt & Whitney, and Honeywell, all of whom depend on tightly controlled TBC application processes. Progressive Surface’s technologies support the automation wave sweeping across the Thermal Barrier Coating Market, enhancing consistency and throughput.

Recent Developments and Market Updates in the Thermal Barrier Coating Market

- In December 2023, Oerlikon announced a breakthrough in nanostructured TBC coatings for high-Mach aircraft engines, capable of withstanding cyclic temperatures above 1800°C. This advancement is aimed at next-generation hypersonic aircraft and reusable space vehicles.

- In July 2023, GE Vernova (a GE spin-off focused on energy) entered a strategic partnership with Praxair Surface Technologies to enhance thermal barrier coating lifespans in HA-class gas turbines, with pilot deployment underway in the UAE and Texas.

- Zircotec launched a new TBC line for solid-state EV battery packs in March 2024, targeting OEMs building next-gen electric vehicles. These coatings provide 30% higher thermal insulation compared to previous products.

- Bodycote expanded its U.S.-based APS and HVOF coating facilities in February 2024, adding capacity to serve growing demand from Rolls-Royce and Siemens Energy.

- In April 2024, China’s COMAC signed a long-term supply agreement with a domestic TBC manufacturer for the C929 wide-body program, signaling a shift toward localization of thermal barrier coating supply chains in Asia.

These strategic moves highlight how innovation, localization, and demand from aerospace, energy, and automotive sectors continue to define the evolving dynamics of the Thermal Barrier Coating Market.

Market Scenario, Demand vs Supply, Average Product Price, Import vs Export, till 2035

- Global Thermal Barrier Coating Market revenue and demand by region

- Global Thermal Barrier Coating Market production and sales volume

- United States Thermal Barrier Coating Market revenue size and demand by country

- Europe Thermal Barrier Coating Market revenue size and demand by country

- Asia Pacific Thermal Barrier Coating Market revenue size and demand by country

- Middle East & Africa Thermal Barrier Coating Market revenue size and demand by country

- Latin America Thermal Barrier Coating Market revenue size and demand by

- Import-export scenario – United States, Europe, APAC, Latin America, Middle East & Africa

- Average product price – United States, Europe, APAC, Latin America, Middle East & Africa

- Market player analysis, competitive scenario, market share analysis

- Business opportunity analysis

Key questions answered in the Global Thermal Barrier Coating Market Analysis Report:

- What is the market size for Thermal Barrier Coating in United States, Europe, APAC, Middle East & Africa, Latin America?

- What is the yearly sales volume of Thermal Barrier Coating and how is the demand rising?

- Who are the top market players by market share, in each product segment?

- Which is the fastest growing business/ product segment?

- What should be the business strategies and Go to Market strategies?

The report covers Thermal Barrier Coating Market revenue, Production, Sales volume, by regions, (further split into countries):

- Asia Pacific (China, Japan, South Korea, India, Indonesia, Vietnam, Rest of APAC)

- Europe (UK, Germany, France, Italy, Spain, Benelux, Poland, Rest of Europe)

- North America (United States, Canada, Mexico)

- Latin America (Brazil, Argentina, Rest of Latin America)

- Middle East & Africa

Table of Contents:

- Introduction to the Thermal Barrier Coating Market

- Definition and Significance of Thermal Barrier Coatings

- Applications Across Industries

- Advancements in Coating Technologies

- Segmentation of the Thermal Barrier Coating Market

- Classification by Coating Material

- Market Breakdown by Application and End-Use Industry

- Innovations in Coating Composition and Performance

- Global Thermal Barrier Coating Market Trends and Growth Forecast (2020-2040)

- Historical Market Trends

- Projected Industry Growth and Emerging Opportunities

- Thermal Barrier Coating Market in North America

- Market Demand and Key Growth Drivers

- Domestic Thermal Barrier Coating Production vs Imports

- Pricing Analysis and Future Market Trends

- Thermal Barrier Coating Market in Europe

- Impact of Regulatory Policies and Environmental Standards

- Key Market Players and Competitive Strategies

- Forecasted Market Performance in the European Region

- Thermal Barrier Coating Market in Asia Pacific

- Expansion of Manufacturing Facilities

- Market Dynamics and Adoption in Key Industries

- Regional Pricing Trends and Forecasts

- Thermal Barrier Coating Market in Latin America

- Market Growth and Investment Potential

- Supply Chain and Distribution Challenges

- Competitive Landscape and Key Players

- Thermal Barrier Coating Market in Middle East & Africa

- Industry Growth Drivers and Challenges

- Role of Thermal Barrier Coatings in High-Temperature Applications

- Future Market Potential and Expansion Plans

- Thermal Barrier Coating Production Analysis and Forecasts (2020-2040)

- Production Volumes by Region

- Technological Innovations in Thermal Barrier Coating Production

- Future Outlook for Global Manufacturing

- Competitive Analysis of Thermal Barrier Coating Manufacturers

- Market Share of Leading Companies

- Key Strategies for Market Positioning

- Research and Development Initiatives

- Global Thermal Barrier Coating Production Landscape

- Regional Manufacturing Capacities and Market Distribution

- Advances in Coating Application Techniques

- Sustainability in Production Processes

- Revenue Market Share of Thermal Barrier Coating Manufacturers (2020-2035)

- Financial Performance of Key Market Players

- Growth Analysis of Leading Companies

- Future Revenue Projections

- Production and Processing Technologies for Thermal Barrier Coatings

- Developments in Manufacturing Techniques

- Efficiency Improvements in Coating Application

- Cost-Effective Production Strategies

- Thermal Barrier Coating Market Revenue, Pricing, and Profitability Analysis (2020-2035)

- Market Price Trends and Influencing Factors

- Profit Margins in Various Market Segments

- Economic Viability of Different Coating Technologies

- Export Trends and Global Demand for Thermal Barrier Coatings

- Leading Exporters and Key Trade Routes

- Impact of Trade Regulations on Market Expansion

- Future Growth Opportunities in Export Markets

- Import Market Analysis for Thermal Barrier Coatings

- Countries with High Import Demand

- Market Advantages of Imported vs Locally Produced Coatings

- Regulatory Factors Affecting Import Trends

- Consumption Trends and Market Demand for Thermal Barrier Coatings

- Key Industries Driving Market Growth

- Technological Advancements Affecting Consumer Preferences

- Demand Projections for Various Applications

- Regional Consumption Analysis of Thermal Barrier Coatings

- Comparative Market Study of Consumption Patterns

- Factors Affecting Regional Demand Fluctuations

- Future Growth Potential in Consumption Markets

- Consumption by Product Type in the Thermal Barrier Coating Market

- Market Share of Various Coating Materials

- Performance Evaluation of Different Product Categories

- Trends Shaping Future Product Development

- Market Share Analysis by Thermal Barrier Coating Product Category

- Revenue Distribution Across Product Segments

- Competitive Positioning of Different Coating Types

- Future Market Expansion of High-Demand Products

- Global Thermal Barrier Coating Production Analysis by Product Type (2020-2040)

- Leading Coating Types in Production Volumes

- Innovations in Coating Formulations

- Projected Market Growth by Product Type

- Revenue Market Share by Thermal Barrier Coating Product Type (2020-2040)

- Financial Contributions of Key Product Categories

- Revenue Trends of Various Coating Segments

- Impact of Innovation on Market Share Growth

- Manufacturing Cost Analysis for Thermal Barrier Coatings

- Breakdown of Production Costs Across Regions

- Key Cost Drivers in Manufacturing Processes

- Strategies for Cost Optimization

- Key Raw Materials for Thermal Barrier Coating Production

- Essential Materials and Their Market Trends

- Pricing and Availability of Critical Inputs

- Supply Chain Risks and Alternative Material Innovations

- Leading Suppliers of Raw Materials for Thermal Barrier Coatings

- Global and Regional Raw Material Sources

- Procurement Strategies for Manufacturers

- Supply Chain Challenges and Future Outlook

- Industrial Chain Analysis of the Thermal Barrier Coating Market

- Market Value Chain from Raw Materials to End-Users

- Role of Logistics in Market Efficiency

- Strategies for Enhancing Supply Chain Performance

- Marketing Strategies, Distribution Networks, and Consumer Engagement

- Key Distribution Models in the Industry

- Digital vs Traditional Sales Channels

- Market Expansion Through Strategic Marketing

- Comprehensive List of Thermal Barrier Coating Distributors

- Leading Distributors and Their Market Presence

- Regional Distribution Analysis

- Growth Strategies of Major Distributors

- Key Partnerships and Collaborations in the Thermal Barrier Coating Market

- Impact of Joint Ventures and Strategic Alliances

- Future Trends in Industry Partnerships

- Case Studies of Successful Market Collaborations

- End-Users and Key Consumers of Thermal Barrier Coatings

- Industries with Highest Demand for Thermal Barrier Coatings

- Strategies for Customer Retention and Market Growth

- Future Demand Trends Based on Industry Needs

- Thermal Barrier Coating Production and Supply Forecast (2025-2040)

- Projected Global Manufacturing Capacities

- Forecasted Market Demand and Production Alignment

- Evolution of the Supply Chain for Thermal Barrier Coating

“Every Organization is different and so are their requirements”- Datavagyanik

Companies We Work With

Do You Want To Boost Your Business?

drop us a line and keep in touch