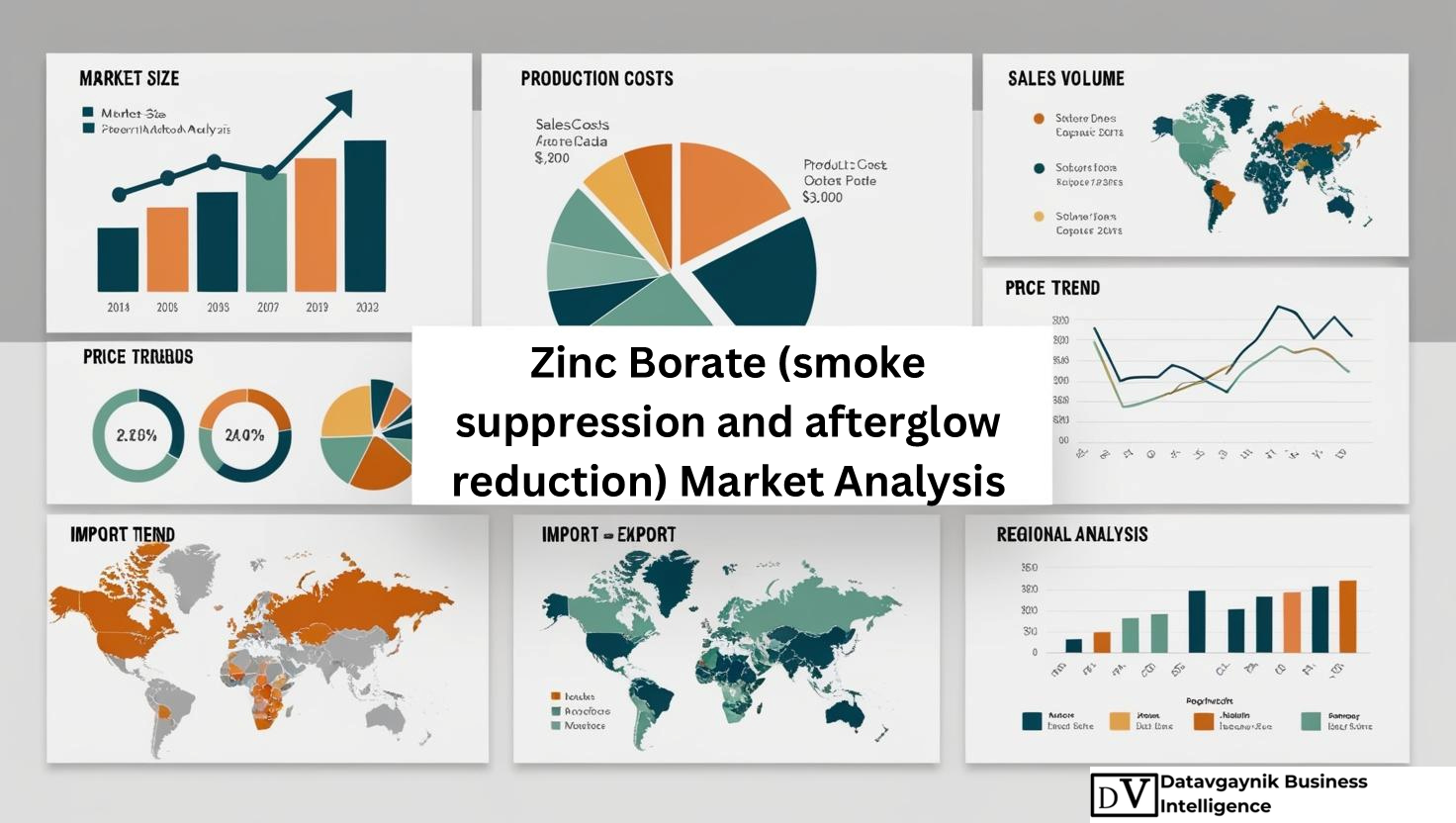

Zinc Borate (smoke suppression and afterglow reduction) Market Size, Production, Sales, Average Product Price, Market Share, Import vs Export

- Published 2025

- No of Pages: 120+

- 20% Customization available

Zinc Borate (Smoke Suppression and Afterglow Reduction) Market Growth Drivers

The Zinc Borate (smoke suppression and afterglow reduction) Market is experiencing significant expansion as industries worldwide increasingly focus on safety, sustainability, and regulatory compliance. Zinc Borate, renowned for its dual functionality in smoke suppression and afterglow reduction, is becoming a crucial material in various sectors, including construction, automotive, and electronics. This growth can be attributed to several key drivers that are shaping the market’s future.

Rising Regulatory Standards in Fire Safety

A major driver of the Zinc Borate (smoke suppression and afterglow reduction) Market is the growing implementation of stringent fire safety regulations. For instance, the construction industry is increasingly adopting fire-resistant materials to comply with updated building codes. In countries like the United States and European Union nations, regulations are tightening to ensure that materials used in residential, commercial, and industrial buildings meet higher safety standards. Zinc Borate’s ability to suppress smoke and reduce afterglow makes it a sought-after additive in fire-resistant building materials such as insulation, coatings, and wiring. These regulatory shifts are directly contributing to the rising demand for Zinc Borate across key industries.

Datavagyanik also covers related markets such as the Zinc Borate Market and the Zinc borate derivatives Market. Such interlinked markets help paint a fuller story of the supply chain, influencing the primary topic’s trajectory.

Growing Demand for Fire Retardant Materials

As global industrialization continues, the demand for fire retardant materials, especially those offering enhanced smoke suppression and afterglow reduction, is increasing. The Zinc Borate (smoke suppression and afterglow reduction) Market is experiencing growth primarily in sectors like construction, automotive, and electronics. In the automotive sector, for example, electric vehicles (EVs) are driving the need for fire-safe materials, with manufacturers prioritizing safety features like smoke suppression and afterglow reduction in battery systems and interiors. The growth of the global electric vehicle market, which is expected to reach a valuation of over USD 800 billion by 2027, plays a crucial role in boosting the demand for Zinc Borate. Similarly, the electronics sector, where fire resistance is essential for consumer goods and circuit boards, has seen an increased adoption of Zinc Borate for improving the safety of electronic devices.

Environmental Concerns and Sustainability

Sustainability concerns are another factor contributing to the growth of the Zinc Borate (smoke suppression and afterglow reduction) Market. In response to environmental issues, many industries are shifting towards more eco-friendly materials, including halogen-free flame retardants. Zinc Borate, being a halogen-free compound, offers an environmentally safer alternative to traditional flame retardants, which are often associated with health and environmental risks. For instance, Zinc Borate’s use in the construction industry helps reduce the overall environmental footprint of fire-resistant materials, which is crucial in regions like Europe, where environmental regulations are stringent. This shift towards safer, sustainable alternatives has positioned Zinc Borate as a preferred option in fire safety applications, particularly in markets that prioritize eco-friendly manufacturing processes.

Technological Advancements in Zinc Borate Formulations

The Zinc Borate (smoke suppression and afterglow reduction) Market is benefiting from continuous technological advancements in the development of Zinc Borate formulations. Manufacturers have made significant strides in enhancing the performance of Zinc Borate under various conditions. For example, the development of formulations that perform well at higher temperatures has expanded the range of applications for Zinc Borate, making it suitable for industries such as automotive, electrical, and aerospace. As technological innovations continue, the Zinc Borate (smoke suppression and afterglow reduction) Market will likely see an increase in demand from diverse sectors that require high-performance, durable fire retardants capable of withstanding extreme conditions.

Increased Awareness of Consumer Safety

Consumer safety is another driving factor for the rising demand for Zinc Borate. There has been an increasing awareness of the potential fire hazards posed by everyday products, including textiles, furniture, and electrical appliances. As a result, manufacturers are increasingly turning to Zinc Borate to enhance the fire resistance of consumer goods. Zinc Borate’s effectiveness in reducing both smoke emissions and afterglow has made it a preferred choice for safety-conscious industries. For instance, in the textile industry, Zinc Borate is used to create fire-resistant fabrics for uniforms, military gear, and safety equipment. The growing focus on consumer safety, coupled with regulations mandating the use of fire-resistant materials in household products, will continue to drive the Zinc Borate (smoke suppression and afterglow reduction) Market.

The Role of Zinc Borate in Halogen-Free Flame Retardant Systems

The increasing preference for halogen-free flame retardants has significantly contributed to the growth of the Zinc Borate (smoke suppression and afterglow reduction) Market. Halogenated flame retardants have been phased out due to their potential environmental and health hazards, and industries are now shifting toward safer alternatives. Zinc Borate fits perfectly into this trend as a halogen-free compound that is both effective and environmentally safe. This transition is particularly noticeable in the construction and automotive industries, where Zinc Borate is now commonly used in materials such as fireproof coatings and wiring. With the global market for halogen-free flame retardants expected to grow at a compound annual growth rate (CAGR) of over 7% through 2028, Zinc Borate is poised to benefit from this significant shift in industry practices.

Zinc Borate (Smoke Suppression and Afterglow Reduction) Market Size and Regional Growth

The Zinc Borate (smoke suppression and afterglow reduction) Market Size is experiencing notable growth in various regions, driven by industry-specific demands. For example, in the United States and Europe, stringent fire safety regulations have led to an increase in the production and use of Zinc Borate across multiple sectors. The market in these regions is particularly strong in the construction, automotive, and electronics industries, where demand for fire-resistant materials is at an all-time high. As industries continue to focus on fire safety and sustainability, the demand for Zinc Borate is expected to rise, positioning the Zinc Borate (smoke suppression and afterglow reduction) Market as a key player in the global fire safety solutions market.

The Impact of Industrialization and Infrastructure Development

The rapid growth of industrial sectors, particularly in emerging economies, is another significant driver of the Zinc Borate (smoke suppression and afterglow reduction) Market. As countries in Asia Pacific, including China and India, continue to industrialize and expand their infrastructure, the demand for fire-resistant materials has surged. For example, China’s construction and automotive industries are significant consumers of Zinc Borate due to the country’s stringent fire safety regulations and its commitment to sustainability. With the market for Zinc Borate expected to grow steadily in the Asia Pacific region, manufacturers are investing in production capacity to meet the increasing demand for this flame retardant across diverse industries.

Consumer Demand for High-Performance Materials

In parallel with regulatory and technological developments, consumer demand for high-performance materials is driving the growth of the Zinc Borate (smoke suppression and afterglow reduction) Market. As industries, particularly those in the automotive, construction, and electronics sectors, look for materials that not only meet safety standards but also enhance performance, Zinc Borate is emerging as a leading solution. In the automotive sector, for instance, the growing demand for electric vehicles, which require advanced fire safety measures in batteries and wiring, has led to an increased adoption of Zinc Borate. Similarly, the electronics sector’s demand for fire-resistant circuit boards and appliances is fueling the market for Zinc Borate.

The Future Outlook for Zinc Borate (Smoke Suppression and Afterglow Reduction) Market

Looking ahead, the Zinc Borate (smoke suppression and afterglow reduction) Market is poised for continued growth, driven by rising industrialization, stringent fire safety standards, and an increasing demand for sustainable, halogen-free materials. As industries around the world continue to prioritize fire safety and environmental sustainability, Zinc Borate’s role as a key component in fire-resistant materials will become even more critical. The market will likely continue to benefit from ongoing technological advancements, regional market growth, and the expanding adoption of Zinc Borate in diverse applications. As such, Zinc Borate is well-positioned to remain a key player in the global fire safety solutions market for the foreseeable future.

“Track Country-wise Zinc Borate (smoke suppression and afterglow reduction) Production and Demand through our Zinc Borate (smoke suppression and afterglow reduction) Production Database”

-

-

- Zinc Borate (smoke suppression and afterglow reduction) production database for 23+ countries worldwide

- Zinc Borate (smoke suppression and afterglow reduction) sales volume for 28+ countries

- Country-wise Zinc Borate (smoke suppression and afterglow reduction) production capacity, production plant mapping, production capacity utilization for 23+ manufacturers

- Zinc Borate (smoke suppression and afterglow reduction) production plants and production plant capacity analysis by top manufacturers

-

“Track real-time Zinc Borate (smoke suppression and afterglow reduction) Prices, Zinc Borate (smoke suppression and afterglow reduction) price charts for 23+ countries, Zinc Borate (smoke suppression and afterglow reduction) weekly price tracker and Zinc Borate (smoke suppression and afterglow reduction) monthly price tracker”

-

-

- Track real-time Zinc Borate (smoke suppression and afterglow reduction) prices and Zinc Borate (smoke suppression and afterglow reduction) price trend in 23+ countries though our excel-based Zinc Borate (smoke suppression and afterglow reduction) price charts

- Real-time Zinc Borate (smoke suppression and afterglow reduction) price tracker dashboard with 23+ countries

- Complete transparency on Zinc Borate (smoke suppression and afterglow reduction) price trend through our Zinc Borate (smoke suppression and afterglow reduction) monthly price tracker, Zinc Borate (smoke suppression and afterglow reduction) weekly price tracker

-

Geographical Demand for Zinc Borate (Smoke Suppression and Afterglow Reduction) Market

The Zinc Borate (smoke suppression and afterglow reduction) Market is witnessing dynamic growth across various global regions. The demand for this compound is increasing rapidly as industries across North America, Europe, Asia Pacific, and beyond recognize the importance of fire safety in their production processes. Each region brings unique challenges and opportunities that drive the adoption of Zinc Borate in various applications.

North America: A Key Driver of Demand

In North America, particularly in the United States, the Zinc Borate (smoke suppression and afterglow reduction) Market is thriving due to stringent fire safety regulations and the growing need for flame retardants in critical industries. The U.S. automotive industry, especially with the rise of electric vehicles (EVs), is a significant contributor to the demand for Zinc Borate. The Zinc Borate (smoke suppression and afterglow reduction) Price is rising in line with increased regulations for safer, more sustainable materials in vehicles. As consumer demand for EVs grows, manufacturers are increasingly relying on Zinc Borate for its ability to reduce afterglow and suppress smoke in automotive parts like wiring, interiors, and battery components.

In the construction sector, the demand for Zinc Borate is fueled by the ongoing emphasis on fire-resistant building materials. Zinc Borate is used extensively in insulation, coatings, and wiring, ensuring fire safety across residential, commercial, and industrial buildings. The Zinc Borate (smoke suppression and afterglow reduction) Market size in North America is expected to continue expanding as new infrastructure projects and the increasing need for fire-resistant materials continue to boost demand.

Europe: Strong Regulatory Support and Growing Adoption

Europe, particularly Germany, the United Kingdom, and France, is witnessing a surge in Zinc Borate demand. As one of the leading regions in industrial manufacturing, the European Zinc Borate (smoke suppression and afterglow reduction) Market is growing rapidly, driven by the construction and automotive sectors. For example, Germany, with its strong focus on sustainable manufacturing practices, has significantly adopted Zinc Borate as a halogen-free flame retardant. The Zinc Borate (smoke suppression and afterglow reduction) Price Trend in Europe is showing an upward trajectory, driven by regulatory frameworks such as the EU REACH regulations, which encourage the use of eco-friendly and safer alternatives to traditional halogenated flame retardants.

The demand for Zinc Borate is particularly high in the automotive sector, where the shift toward electric vehicles and more sustainable car manufacturing is creating a need for high-performance, fire-safe materials. France and the UK are also significant contributors to Zinc Borate adoption, with the growing focus on fire safety in building materials and automotive components driving the Zinc Borate (smoke suppression and afterglow reduction) Market. The increase in fire safety regulations and sustainability efforts within the European Union is expected to continue fueling the market in the coming years.

Asia Pacific: Rising Demand in Emerging Economies

Asia Pacific is seeing explosive growth in the Zinc Borate (smoke suppression and afterglow reduction) Market, driven by industrialization and rapid urbanization. Countries such as China, India, Japan, and South Korea are the primary drivers of this growth. For example, China, as the world’s largest producer of Zinc Borate, is also a major consumer due to its expanding construction, automotive, and electronics sectors. The increasing demand for electric vehicles and fire-resistant materials in the construction industry in China has contributed to the rise in demand for Zinc Borate. In line with the growing consumer awareness about environmental safety, Chinese manufacturers are focusing on producing more eco-friendly Zinc Borate formulations, which aligns with the country’s stricter environmental regulations.

In India, the Zinc Borate (smoke suppression and afterglow reduction) Market is experiencing growth driven by the rapid expansion of the automotive and infrastructure sectors. As India modernizes its infrastructure, there is an increasing need for fire-resistant materials in building materials, coatings, and wiring. The rising demand for fire-safe materials in both the construction and automotive sectors is directly influencing the Zinc Borate (smoke suppression and afterglow reduction) Price trend, with manufacturers increasingly seeking affordable and efficient flame retardants.

Japan and South Korea, known for their technological advancements and high manufacturing standards, also represent significant markets for Zinc Borate. The demand for Zinc Borate in these countries is primarily driven by the electronics and automotive industries. The rising adoption of electric vehicles and the growing need for fire-safe electronic components are expected to further propel the demand for Zinc Borate. The Zinc Borate (smoke suppression and afterglow reduction) Price trend in Japan is showing a stable increase as manufacturers continue to prioritize both safety and environmental considerations in their product offerings.

Latin America and the Middle East: Emerging Markets for Zinc Borate

The Zinc Borate (smoke suppression and afterglow reduction) Market is also seeing growth in emerging markets in Latin America and the Middle East. Countries like Brazil and Mexico are investing heavily in infrastructure development, creating opportunities for Zinc Borate in construction materials such as fire-resistant coatings and insulation. The increasing demand for fire-safe materials in urban development projects is directly contributing to the growth of Zinc Borate in the region. As industrialization accelerates and regulations on fire safety become more stringent, the market for Zinc Borate in Latin America is expected to expand significantly.

In the Middle East, particularly in the UAE and Saudi Arabia, there is an increasing demand for fire-resistant materials due to rapid urbanization and infrastructure projects. The Zinc Borate (smoke suppression and afterglow reduction) Market in the Middle East is growing as construction companies seek effective fire retardants for high-rise buildings, public infrastructure, and residential projects. The region’s demand for Zinc Borate is also being driven by the automotive sector, where the rising need for fire-safe materials in vehicle interiors and electrical systems is creating opportunities for producers of Zinc Borate.

Zinc Borate (Smoke Suppression and Afterglow Reduction) Market Segmentation

The Zinc Borate (smoke suppression and afterglow reduction) Market is segmented by application, product type, and end-use industry, each contributing to the overall market growth.

By Application: Construction, Automotive, Electronics, and More

In the construction industry, Zinc Borate is widely used in insulation, coatings, and wiring materials due to its ability to suppress smoke and reduce afterglow. The increasing focus on fire safety in both commercial and residential buildings is propelling the demand for Zinc Borate. In the automotive sector, Zinc Borate is used in electrical systems, battery components, and interior materials to ensure fire safety in vehicles. The growth of electric vehicles, which require advanced fire safety measures, has led to a significant rise in Zinc Borate adoption. In electronics, Zinc Borate is utilized in circuit boards, wiring, and appliances to enhance fire resistance, ensuring the safety and longevity of electrical products.

By Product Type: Standard and Eco-friendly Zinc Borate

The Zinc Borate (smoke suppression and afterglow reduction) Market is also segmented by product type, with eco-friendly Zinc Borate formulations gaining popularity. As industries shift toward more sustainable practices, eco-friendly Zinc Borate, which is halogen-free and non-toxic, is increasingly preferred over traditional formulations. This trend is particularly prevalent in regions like Europe and North America, where stringent environmental regulations are pushing manufacturers to adopt safer and more sustainable materials. The demand for eco-friendly Zinc Borate is expected to continue growing as regulatory frameworks become stricter and consumers prioritize environmentally responsible products.

Zinc Borate (Smoke Suppression and Afterglow Reduction) Price Trends

The Zinc Borate (smoke suppression and afterglow reduction) Price trend reflects the growing demand for fire-safe materials across multiple industries. As demand increases, particularly in sectors like automotive and construction, the price of Zinc Borate has been steadily rising. The shift toward halogen-free, eco-friendly formulations is contributing to this price increase, as manufacturers invest in more sustainable production processes. Additionally, global supply chain challenges and the increasing cost of raw materials are factors influencing the Zinc Borate (smoke suppression and afterglow reduction) Price. As market demand continues to grow, particularly in emerging economies, prices are expected to stabilize, but the focus on higher-quality, more sustainable formulations may continue to drive upward pressure on prices.

Conclusion

The Zinc Borate (smoke suppression and afterglow reduction) Market is poised for continued growth across regions, driven by increasing industrialization, regulatory pressures, and the growing demand for fire-safe, eco-friendly materials. North America, Europe, and Asia Pacific are expected to remain key markets, while emerging economies in Latin America and the Middle East present new opportunities for producers. The market is segmented across various applications, product types, and industries, with price trends reflecting the growing preference for sustainable formulations. As industries worldwide prioritize safety and environmental sustainability, the Zinc Borate (smoke suppression and afterglow reduction) Market will continue to expand, driven by both regional demand and global regulatory shifts.

“Zinc Borate (smoke suppression and afterglow reduction) Manufacturing Database, Zinc Borate (smoke suppression and afterglow reduction) Manufacturing Capacity”

-

-

- Zinc Borate (smoke suppression and afterglow reduction) top manufacturers market share for 23+ manufacturers

- Top 7 manufacturers and top 13 manufacturers of Zinc Borate (smoke suppression and afterglow reduction) in North America, Europe, Asia Pacific

- Zinc Borate (smoke suppression and afterglow reduction) production plant capacity by manufacturers and Zinc Borate (smoke suppression and afterglow reduction) production data for 23+ market players

- Zinc Borate (smoke suppression and afterglow reduction) production dashboard, Zinc Borate (smoke suppression and afterglow reduction) production data in excel format

-

“Zinc Borate (smoke suppression and afterglow reduction) price charts, Zinc Borate (smoke suppression and afterglow reduction) weekly price tracker and Zinc Borate (smoke suppression and afterglow reduction) monthly price tracker”

-

-

- Factors impacting real-time Zinc Borate (smoke suppression and afterglow reduction) prices in 18+ countries worldwide

- Zinc Borate (smoke suppression and afterglow reduction) monthly price tracker, Zinc Borate (smoke suppression and afterglow reduction) weekly price tracker

- Real-time Zinc Borate (smoke suppression and afterglow reduction) price trend, Zinc Borate (smoke suppression and afterglow reduction) price charts, news and updates

- Tracking Zinc Borate (smoke suppression and afterglow reduction) price fluctuations

-

Top Manufacturers in the Zinc Borate (Smoke Suppression and Afterglow Reduction) Market

The Zinc Borate (smoke suppression and afterglow reduction) Market is dominated by a few major manufacturers that are recognized for their high-quality products and global presence. These companies are driving market growth by producing advanced Zinc Borate formulations that meet the evolving fire safety standards across various industries, including construction, automotive, and electronics. Below is a list of some of the top manufacturers and their product lines that are shaping the market.

- U.S. Borax Inc.

U.S. Borax, a subsidiary of Rio Tinto, is one of the leading producers of Zinc Borate and has a strong foothold in the global market. The company produces a range of Zinc Borate formulations tailored for various applications, including its Zinc Borate 333, which is widely used in plastics and rubber as a flame retardant. U.S. Borax is known for its commitment to sustainability and safety, offering halogen-free Zinc Borate products that align with environmental regulations. Their products are used extensively in construction, automotive, and electronics sectors.

- Borax Europe Ltd.

Borax Europe Ltd., part of the worldwide Borax group, is another major player in the Zinc Borate market. The company manufactures Zinc Borate products that cater to a wide array of applications, including fire-resistant coatings, insulation, and plastics. Their product line includes Zinc Borate 2H, which is commonly used in the construction and automotive industries for smoke suppression and afterglow reduction. Borax Europe’s products are well-regarded for their high performance, ensuring they meet international fire safety standards.

- Doo-Il Chemical Co., Ltd.

Doo-Il Chemical, based in South Korea, is a significant manufacturer of Zinc Borate and specializes in the production of high-quality, eco-friendly flame retardants. Their product lines include Doo-Il Zinc Borate, which is used in automotive, construction, and electrical industries to enhance fire safety. The company focuses heavily on the development of environmentally safe Zinc Borate formulations, which align with global trends toward halogen-free products. Doo-Il Chemical has made substantial strides in increasing production capacity to meet growing global demand, particularly in the Asia Pacific region.

- Zhangqiu Yulong Chemical Co., Ltd.

Zhangqiu Yulong Chemical is one of the largest producers of Zinc Borate in China, serving industries in both domestic and international markets. Their product range includes Yulong Zinc Borate, which is primarily used in construction and automotive applications. The company’s focus on technological innovation has led to the development of high-performance Zinc Borate formulations that offer improved smoke suppression and afterglow reduction properties. Yulong Chemical has capitalized on the rapid industrialization in China and other emerging markets, positioning itself as a key supplier of Zinc Borate in Asia Pacific.

- Hunan Hongguang Chemical Co., Ltd.

Hunan Hongguang Chemical is another major manufacturer of Zinc Borate based in China. They produce a variety of Zinc Borate grades, including HG Zinc Borate, designed for use in plastics, coatings, and automotive applications. Hunan Hongguang has been focusing on improving product quality and sustainability, with an emphasis on reducing the environmental impact of its products. The company is increasing its production capacity to meet the growing demand from industries such as construction, electronics, and automotive.

Market Share by Manufacturers

The Zinc Borate (smoke suppression and afterglow reduction) Market is highly competitive, with a handful of large manufacturers capturing a significant portion of the market share. As of recent market analyses, the largest share of the Zinc Borate market is held by U.S. Borax, followed closely by Borax Europe Ltd. These two companies lead the market due to their global reach, well-established product lines, and ongoing investment in sustainable and eco-friendly solutions.

In Asia Pacific, manufacturers like Doo-Il Chemical and Zhangqiu Yulong Chemical are leading the charge. These companies dominate the market in China, India, and other emerging economies where industrialization is rapidly accelerating. Due to the rapid demand for fire-safe materials in construction, automotive, and electronics sectors in these regions, they are expected to continue growing their market share.

While the Zinc Borate (smoke suppression and afterglow reduction) Market remains dominated by these top manufacturers, smaller players are emerging in local markets, especially in regions like Southeast Asia and Latin America. These players are focusing on offering cost-effective Zinc Borate formulations that meet local demand for fire-resistant materials in construction and automotive sectors.

Recent News and Industry Developments

The Zinc Borate (smoke suppression and afterglow reduction) Market has witnessed several key developments in recent months, with industry leaders pushing forward with technological advancements, product innovations, and sustainability initiatives.

- U.S. Borax Expands Production Capacity – In March 2025, U.S. Borax announced a major expansion of its Zinc Borate production facility in California. This move is expected to increase the company’s capacity by 25%, meeting the growing demand for Zinc Borate in the automotive and construction industries. The expansion will also allow the company to produce more eco-friendly Zinc Borate formulations, supporting the shift towards sustainable, halogen-free flame retardants.

- Doo-Il Chemical Launches New Eco-Friendly Product Line – In February 2025, Doo-Il Chemical introduced a new range of eco-friendly Zinc Borate products under the brand name Doo-Il Green Borate. This line is designed to meet the increasing demand for non-toxic, halogen-free flame retardants, particularly in the automotive and electronics sectors. The launch aligns with global sustainability trends and has received positive feedback from manufacturers seeking safer alternatives to traditional flame retardants.

- Zhangqiu Yulong Chemical Partners with European Construction Giants – In January 2025, Zhangqiu Yulong Chemical entered into a strategic partnership with several leading construction companies in Germany. The collaboration focuses on the use of Zinc Borate in fire-resistant building materials for high-rise buildings and residential complexes. This partnership is expected to significantly increase the company’s market share in Europe, where fire safety regulations are becoming more stringent.

- Hunan Hongguang Chemical Invests in New R&D Facility – In December 2024, Hunan Hongguang Chemical announced an investment of USD 15 million in a new research and development facility in China. The facility will focus on developing advanced Zinc Borate formulations with improved smoke suppression and afterglow reduction properties. The investment aims to strengthen the company’s position as a key player in the global Zinc Borate market and cater to the increasing demand from the automotive and construction sectors.

- Zinc Borate Price Fluctuations – As of early 2025, the Zinc Borate (smoke suppression and afterglow reduction) Price has been steadily rising due to increased demand in key regions, particularly in North America and Europe. Supply chain disruptions and the increasing cost of raw materials have contributed to the rise in prices. Manufacturers are working to mitigate these challenges by improving production efficiencies and exploring alternative sourcing strategies to keep costs manageable.

Conclusion

The Zinc Borate (smoke suppression and afterglow reduction) Market is dominated by major manufacturers like U.S. Borax, Borax Europe Ltd., Doo-Il Chemical, Zhangqiu Yulong Chemical, and Hunan Hongguang Chemical, who continue to innovate and expand production capacities to meet the growing demand for fire-resistant materials. These companies lead the market in terms of product offerings, with a focus on eco-friendly and high-performance formulations. Market share by manufacturers shows a healthy distribution, with strong growth prospects in emerging economies, particularly in Asia Pacific. Recent developments, including new product lines, strategic partnerships, and investments in R&D, indicate that the Zinc Borate market is poised for continued expansion.

“Zinc Borate (smoke suppression and afterglow reduction) Production Data and Zinc Borate (smoke suppression and afterglow reduction) Production Trend, Zinc Borate (smoke suppression and afterglow reduction) Production Database and forecast”

-

-

- Zinc Borate (smoke suppression and afterglow reduction) production database for historical years, 10 years historical data

- Zinc Borate (smoke suppression and afterglow reduction) production data and forecast for next 7 years

- Zinc Borate (smoke suppression and afterglow reduction) sales volume by manufacturers

-

“Track Real-time Zinc Borate (smoke suppression and afterglow reduction) Prices for purchase and sales contracts, Zinc Borate (smoke suppression and afterglow reduction) price charts, Zinc Borate (smoke suppression and afterglow reduction) weekly price tracker and Zinc Borate (smoke suppression and afterglow reduction) monthly price tracker”

-

-

- Gain control on your purchase and sales contracts through our real-time Zinc Borate (smoke suppression and afterglow reduction) price tracker and Zinc Borate (smoke suppression and afterglow reduction) price trend analysis

- Zinc Borate (smoke suppression and afterglow reduction) weekly price tracker and forecast for next four weeks

- Zinc Borate (smoke suppression and afterglow reduction) monthly price tracker and forecast for next two months

-

Market Scenario, Demand vs Supply, Average Product Price, Import vs Export, till 2035

- Global Zinc Borate (smoke suppression and afterglow reduction) Market revenue and demand by region

- Global Zinc Borate (smoke suppression and afterglow reduction) Market production and sales volume

- United States Zinc Borate (smoke suppression and afterglow reduction) Market revenue size and demand by country

- Europe Zinc Borate (smoke suppression and afterglow reduction) Market revenue size and demand by country

- Asia Pacific Zinc Borate (smoke suppression and afterglow reduction) Market revenue size and demand by country

- Middle East & Africa Zinc Borate (smoke suppression and afterglow reduction) Market revenue size and demand by country

- Latin America Zinc Borate (smoke suppression and afterglow reduction) Market revenue size and demand by

- Import-export scenario – United States, Europe, APAC, Latin America, Middle East & Africa

- Average product price – United States, Europe, APAC, Latin America, Middle East & Africa

- Market player analysis, competitive scenario, market share analysis

- Business opportunity analysis

Key questions answered in the Global Zinc Borate (smoke suppression and afterglow reduction) Market Analysis Report:

- What is the market size for Zinc Borate (smoke suppression and afterglow reduction) in United States, Europe, APAC, Middle East & Africa, Latin America?

- What is the yearly sales volume of Zinc Borate (smoke suppression and afterglow reduction) and how is the demand rising?

- Who are the top market players by market share, in each product segment?

- Which is the fastest growing business/ product segment?

- What should be the business strategies and Go to Market strategies?

The report covers Zinc Borate (smoke suppression and afterglow reduction) Market revenue, Production, Sales volume, by regions, (further split into countries):

- Asia Pacific (China, Japan, South Korea, India, Indonesia, Vietnam, Rest of APAC)

- Europe (UK, Germany, France, Italy, Spain, Benelux, Poland, Rest of Europe)

- North America (United States, Canada, Mexico)

- Latin America (Brazil, Argentina, Rest of Latin America)

- Middle East & Africa

Table of Contents:

Introduction to Zinc Borate and Its Role in Smoke Suppression and Afterglow Reduction

1.1 Overview of Zinc Borate and Its Chemical Composition

1.2 History and Development of Zinc Borate for Smoke Suppression

1.3 Key Benefits of Zinc Borate in Reducing Afterglow in Materials

Chemical Properties and Structure of Zinc Borate

2.1 Molecular Structure and Characteristics of Zinc Borate

2.2 Thermal and Flame Retardant Properties of Zinc Borate

2.3 Mechanisms Behind Smoke Suppression and Afterglow Reduction

Production Methods of Zinc Borate

3.1 Conventional Production Techniques for Zinc Borate

3.2 Innovations in Zinc Borate Manufacturing for Enhanced Performance

3.3 Environmental and Sustainability Considerations in Zinc Borate Production

Market Overview of Zinc Borate

4.1 Global Market Size and Growth Trends for Zinc Borate

4.2 Key Drivers of Zinc Borate Demand in Smoke Suppression Applications

4.3 Market Forecast and Future Growth Opportunities for Zinc Borate

Applications of Zinc Borate in Smoke Suppression

5.1 Use of Zinc Borate in Plastics and Polymers for Smoke Suppression

5.2 Zinc Borate in Coatings and Paints for Fire Safety

5.3 Role of Zinc Borate in Electrical and Electronic Components for Smoke Control

5.4 Applications of Zinc Borate in Construction Materials for Fire Resistance

Zinc Borate for Afterglow Reduction

6.1 Understanding Afterglow and Its Impact on Material Safety

6.2 Use of Zinc Borate in Reducing Afterglow in Fire-Retardant Products

6.3 Enhancing Material Performance and Safety Through Afterglow Reduction

Market Segmentation by Application

7.1 Segmentation of Zinc Borate Demand by Industry: Polymers, Coatings, Electronics, etc.

7.2 Regional Market Insights and Demand Trends for Zinc Borate

7.3 Application-Specific Growth Drivers in the Zinc Borate Market

End-User Industry Insights

8.1 Plastics Industry: The Role of Zinc Borate in Smoke Suppression and Afterglow Reduction

8.2 Construction and Building Materials: Enhancing Fire Safety with Zinc Borate

8.3 Electronics Industry: Smoke Control and Afterglow Mitigation with Zinc Borate

8.4 Automotive Industry: Applications of Zinc Borate in Fire-Resistant Materials

Regional Market Dynamics

9.1 North America: Market Trends and Key Players in Zinc Borate Demand

9.2 Europe: Regulatory Influence on Zinc Borate Adoption and Use

9.3 Asia-Pacific: Growth Opportunities and Zinc Borate Production Hub

9.4 Latin America: Emerging Markets and Zinc Borate Applications

9.5 Middle East & Africa: Development Potential and Market Challenges

Competitive Landscape in the Zinc Borate Market

10.1 Key Players and Market Share in the Zinc Borate Industry

10.2 Mergers, Acquisitions, and Strategic Partnerships in the Zinc Borate Market

10.3 Focus on Research and Development in Zinc Borate Products for Smoke Suppression

Production Capacity and Supply Chain of Zinc Borate

11.1 Global Zinc Borate Production Capacities and Manufacturing Locations

11.2 Challenges in the Zinc Borate Supply Chain and Raw Material Sourcing

11.3 Strategies for Improving Supply Chain Efficiency in Zinc Borate Production

Pricing Trends and Market Economics of Zinc Borate

12.1 Pricing Dynamics and Key Factors Influencing Zinc Borate Costs

12.2 Production Cost Structure and Pricing Models for Zinc Borate

12.3 Future Price Projections and Economic Impact on the Zinc Borate Market

Demand Forecast and Consumption Patterns

13.1 Forecasted Demand Growth in Zinc Borate Markets by Industry Segment

13.2 Shifts in Consumption Patterns Across Different Regions

13.3 Key Factors Influencing Long-Term Consumption of Zinc Borate

Technological Innovations in Zinc Borate Production

14.1 Advances in Zinc Borate Manufacturing Processes

14.2 Technological Developments in Enhancing Smoke Suppression and Afterglow Reduction

14.3 The Role of Innovation in Expanding Zinc Borate Applications

Environmental and Sustainability Impact of Zinc Borate

15.1 Environmental Benefits of Zinc Borate in Fire Safety and Smoke Control

15.2 Sustainability in Zinc Borate Production and Its Role in Green Building Materials

15.3 Regulatory Compliance and Eco-Friendly Practices in Zinc Borate Manufacturing

Market Outlook and Future Trends (2025-2035)

16.1 Long-Term Growth Projections for the Zinc Borate Market

16.2 Emerging Applications and Innovations for Zinc Borate

16.3 Key Challenges and Risks Impacting the Zinc Borate Industry

Strategic Recommendations for Market Stakeholders

17.1 Market Entry Strategies for New Participants in the Zinc Borate Industry

17.2 Risk Management Approaches for Zinc Borate Manufacturers

17.3 Strategic Collaborations and Partnerships to Strengthen Market Position

Other recently published reports:

“Every Organization is different and so are their requirements”- Datavagyanik

Companies We Work With

Do You Want To Boost Your Business?

drop us a line and keep in touch