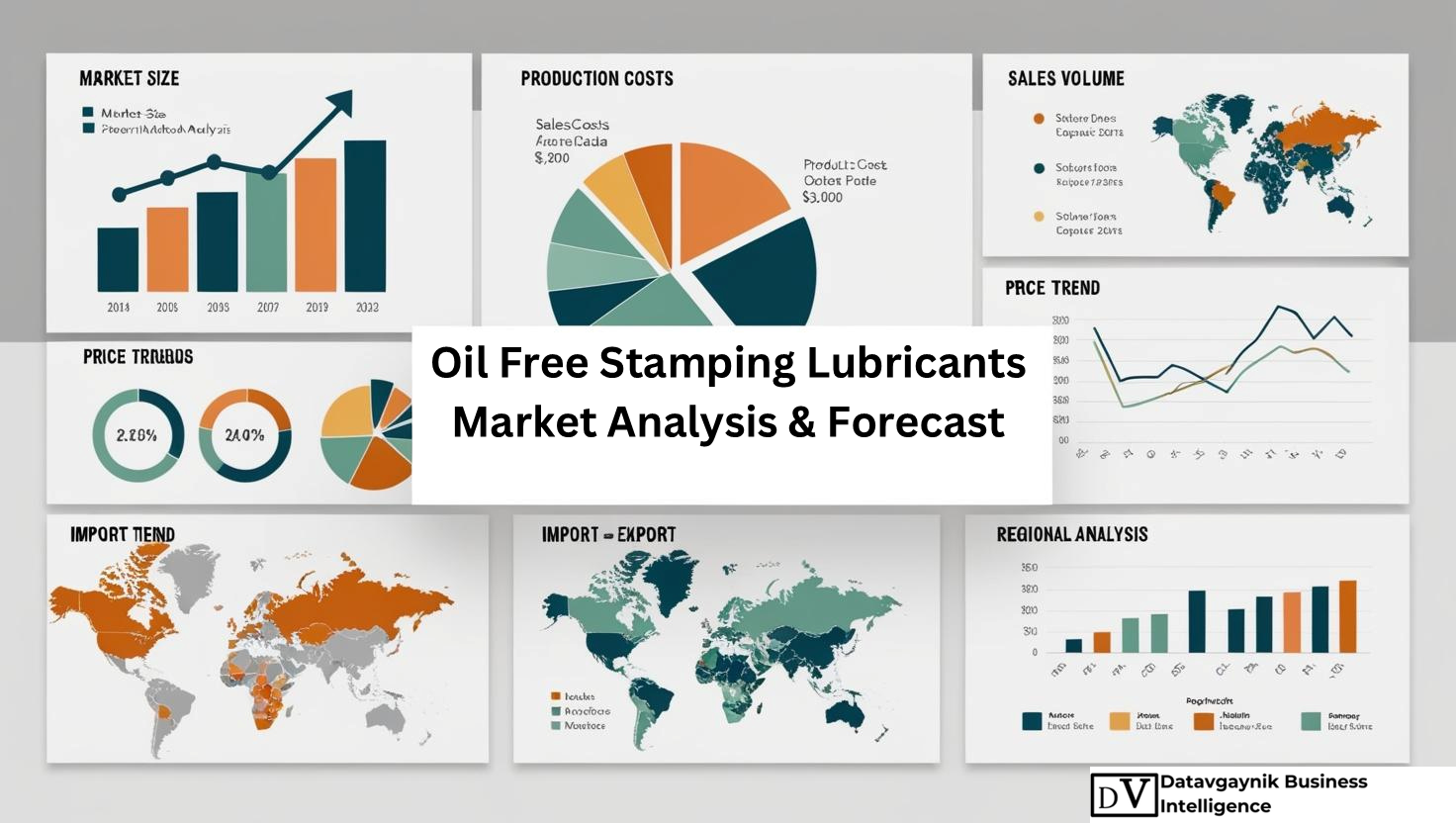

Oil Free Stamping Lubricants Market Size, Production, Sales, Average Product Price, Market Share, Import vs Export

- Published 2025

- No of Pages: 120+

- 20% Customization available

Surging Demand and Growth Outlook in the Oil Free Stamping Lubricants Market

The Oil Free Stamping Lubricants Market is witnessing robust expansion across multiple geographies, backed by structural shifts in manufacturing, environmental compliance imperatives, and technological innovation. A key driver behind this growth is the increasing global emphasis on sustainable and eco-efficient manufacturing practices. For instance, in 2023 alone, over 62% of metal forming and automotive component manufacturers in Europe reported transitioning to water-based or synthetic lubricants, marking a clear departure from petroleum-based oils. The surge in electric vehicle (EV) production has further fueled demand. EV-related stamping operations, which require ultra-precise and residue-free components, have grown at a CAGR of 21.7% between 2020 and 2024, directly impacting the scale of the Oil Free Stamping Lubricants Market.

Environmental Compliance Accelerating Oil Free Stamping Lubricants Market Adoption

Governments and regulatory bodies are intensifying the pressure on manufacturers to phase out hazardous and pollutive lubricants. The Oil Free Stamping Lubricants Market has responded with innovations that deliver high-performance without compromising on environmental safety. For example, companies operating under REACH compliance in Europe and EPA standards in the United States are increasingly opting for oil-free alternatives that offer low-VOC emissions and biodegradable properties. Between 2021 and 2024, adoption of environmentally friendly lubricants grew by more than 34% in Germany’s metalworking sector alone. These shifts are not merely regulatory responses—they represent a long-term transition in manufacturing strategies.

Oil Free Stamping Lubricants Market Fueled by Technological Advancements in Formulation

The evolution of lubricant chemistry is another pillar of growth in the Oil Free Stamping Lubricants Market. Advanced formulations using synthetic esters, polyalkylene glycols, and micro-emulsion technologies now offer superior anti-wear, cooling, and friction-reducing properties. For instance, in the aerospace sector, these lubricants enable precise metal forming even under extreme pressure and temperature conditions. In 2024, aerospace-grade stamping lubricants represented 11.4% of the total oil-free lubricant consumption in North America, up from 8.2% just three years prior. The increased performance efficiency and extended tool life enabled by these new chemistries are creating competitive differentiation in sectors that rely on precision engineering.

Automotive Industry Transforming the Oil Free Stamping Lubricants Market

The automotive sector remains the largest end-use industry in the Oil Free Stamping Lubricants Market, accounting for over 48% of global demand in 2024. This demand surge is tightly linked to the need for high-throughput metal stamping processes in EV manufacturing, where clean stamping with no residue or smoke is essential. For example, EV battery casing production requires tight tolerances and flawless surface finishes—conditions under which traditional oil-based lubricants tend to underperform due to residue buildup. In comparison, oil-free formulations reduce post-processing costs by up to 23% and eliminate the need for complex solvent-based cleaning. With EV production expected to exceed 16 million units globally by 2026, the demand trajectory for oil-free stamping lubricants is firmly upward.

Sustainability Goals Reinforcing the Oil Free Stamping Lubricants Market Trajectory

Corporate sustainability commitments are further anchoring growth in the Oil Free Stamping Lubricants Market. For instance, several multinational OEMs such as BMW, Ford, and Schneider Electric have pledged to reduce their scope 3 emissions by 30–50% by 2030. Switching to biodegradable stamping lubricants is a low-hanging fruit in achieving these goals. In a 2024 industry-wide survey conducted across 250 Tier-1 automotive suppliers, nearly 71% identified oil-free stamping lubricants as integral to their decarbonization strategy. These shifts represent a structural change rather than a temporary adjustment, creating long-term opportunities for lubricant manufacturers offering compliant, performance-driven products.

Expansion in Electronics Manufacturing Boosting the Oil Free Stamping Lubricants Market

The miniaturization of electronics components and the increasing complexity of device architecture are creating new demand pockets within the Oil Free Stamping Lubricants Market. For example, in semiconductor casing and heat sink production, precision metal forming is essential, and oil-free lubricants provide the clean finish and low-residue performance required. Asia Pacific, which houses nearly 75% of global electronics production, is a key driver. Between 2020 and 2024, the region saw a 29% rise in demand for water-based and synthetic lubricants in electronics stamping applications. Countries like South Korea and Taiwan have rapidly scaled their local production of oil-free stamping lubricants to meet the growing demand from electronics OEMs.

High-Speed Manufacturing Trends Accelerate Oil Free Stamping Lubricants Market Demand

As industries transition toward high-speed, automated manufacturing processes, the demand for lubricants that can perform under these conditions has intensified. The Oil Free Stamping Lubricants Market is at the forefront of this transformation, with new formulations designed specifically for high-speed presses operating at over 600 strokes per minute. For instance, in high-volume production environments like automotive body stamping and appliance manufacturing, oil-free lubricants reduce thermal buildup and die wear, enabling longer operational uptime. Companies adopting these lubricants have reported up to a 19% increase in equipment lifecycle and a 14% reduction in overall downtime. This operational efficiency directly translates to better throughput and reduced operational costs.

Rising Popularity of Biodegradable Solutions in the Oil Free Stamping Lubricants Market

The shift toward biodegradable lubricants is gaining momentum within the Oil Free Stamping Lubricants Market, particularly in regions with aggressive environmental mandates. In France, where the manufacturing sector contributes over 10% to the national GDP, adoption of plant-based lubricants has grown at a CAGR of 16.3% since 2021. Biodegradable stamping lubricants, often derived from esters and renewable feedstocks, decompose naturally and reduce waste treatment costs. Industries such as packaging and consumer electronics—where sustainability is a customer-facing concern—are increasingly specifying the use of such lubricants. This has created a ripple effect across supplier ecosystems, pushing lubricant producers to prioritize bio-based innovation.

Regional Manufacturing Policies Influencing the Oil Free Stamping Lubricants Market

Geopolitical trends and regional manufacturing policies are also shaping the Oil Free Stamping Lubricants Market. The U.S. Inflation Reduction Act and Europe’s Green Deal are examples of policy frameworks that incentivize domestic and clean production. As a result, local manufacturers are investing in advanced metal forming operations using oil-free lubricants to secure government contracts and tax benefits. In India, the “Make in India” initiative has led to a 22% increase in the establishment of stamping facilities for electronics and automotive parts between 2022 and 2024. These new facilities are favoring oil-free lubrication systems to align with upcoming sustainability disclosures and ESG benchmarks.

Cost Efficiency and Operational Benefits Driving Oil Free Stamping Lubricants Market Adoption

One of the underappreciated advantages of the Oil Free Stamping Lubricants Market is its impact on total cost of ownership. While oil-free products may carry a marginally higher unit price, their holistic benefits far outweigh the cost differential. For instance, users experience reduced need for degreasing, elimination of VOC capture systems, lower maintenance overheads, and less frequent lubricant disposal. In a 2023 operational audit conducted by a leading Japanese automotive supplier, switching to oil-free lubricants in two production lines resulted in a 17% cost saving over 12 months. These operational advantages are compelling more companies to re-evaluate their lubrication strategies.

North America Remains a Key Growth Pillar in the Oil Free Stamping Lubricants Market

The Oil Free Stamping Lubricants Market in North America continues to expand rapidly, driven by manufacturing modernization, environmental legislation, and the reshoring of industrial activity. The United States, in particular, represents over 35% of the region’s consumption of oil-free stamping lubricants, supported by strong demand from the automotive, aerospace, and electronics sectors. For example, the growing need for high-precision components in electric vehicles and aviation has led to a surge in lubricant demand that offers clean, residue-free performance.

Datavagyanik observes that more than 64% of Tier-1 automotive suppliers in the Midwest shifted to oil-free stamping solutions between 2021 and 2024. This transition was catalyzed by reduced cleaning requirements, improved die life, and compliance with OSHA and EPA emission standards. Canada is also showing double-digit growth in this space, particularly in its aerospace hubs of Ontario and Quebec, where manufacturers prioritize lubricants with superior anti-wear and cooling properties during stamping of high-tolerance alloys.

Europe’s Policy-Driven Shift Powering the Oil Free Stamping Lubricants Market

In Europe, the Oil Free Stamping Lubricants Market has firmly aligned with the continent’s green industrial strategy. Germany, France, and Italy account for more than 60% of total regional demand, primarily due to their advanced automotive and precision engineering sectors. For instance, Germany’s automotive output crossed 4.1 million vehicles in 2023, and over 78% of its component suppliers have incorporated oil-free stamping lubricants to align with both environmental directives and OEM requirements.

France’s market is also expanding, particularly in response to the growing popularity of electric vehicles. French EV production surged by 19.6% in 2024, amplifying the requirement for high-quality stamping operations, especially for lightweight components. In Italy, the integration of oil-free stamping lubricants in the production of aircraft interiors and industrial automation systems is gaining ground. Italian manufacturers are adopting hybrid synthetic formulations that provide longer cycle times and reduced equipment downtime, improving efficiency across the stamping value chain.

Asia Pacific Leading Global Production in the Oil Free Stamping Lubricants Market

The Asia Pacific region dominates global production and consumption in the Oil Free Stamping Lubricants Market, accounting for more than 45% of the total volume in 2024. This dominance is underpinned by the region’s manufacturing base, which serves global supply chains in automotive, electronics, and heavy machinery. China leads the charge, with over 800,000 tons of stamping lubricant consumed in 2024 alone, nearly 60% of which were oil-free formulations.

In China’s Guangdong and Zhejiang provinces—home to large electronics and consumer appliance clusters—oil-free stamping lubricants are critical for achieving high-yield, low-waste operations. Japanese manufacturers, known for precision stamping of electrical connectors and casings, have been early adopters of biodegradable and synthetic stamping solutions. More than 72% of stamping facilities in Japan now run exclusively on oil-free lubrication systems, aiming to meet zero-waste and zero-emission benchmarks by 2030.

India is another fast-growing market, with its automotive and white goods sectors adopting cleaner manufacturing practices. The Indian Oil Free Stamping Lubricants Market is forecasted to grow at a CAGR of 11.2% through 2028, fueled by domestic EV production and government mandates on industrial wastewater treatment. Companies in Pune and Chennai have reported a 20% improvement in stamping throughput since switching to synthetic, oil-free lubrication systems.

Middle East and Africa Gaining Traction in the Oil Free Stamping Lubricants Market

Although smaller in volume, the Oil Free Stamping Lubricants Market in the Middle East and Africa is showing significant potential. Countries such as the UAE and Saudi Arabia are investing in industrial diversification, particularly in non-oil sectors like aluminum processing and electrical appliances. For example, metal forming plants in Jeddah have increased their use of oil-free lubricants by 38% between 2022 and 2024 to comply with new environmental laws and to reduce equipment failure in high-temperature environments.

In South Africa, the mining equipment and construction machinery sectors are early adopters of oil-free stamping lubricants. Their demand stems from the need to extend die life and minimize wear in rugged applications. As the region’s industrial base matures, the Oil Free Stamping Lubricants Market will continue to benefit from the trend toward greener manufacturing standards.

Latin America Demonstrating Steady Progress in the Oil Free Stamping Lubricants Market

Latin America is emerging as a growth frontier for the Oil Free Stamping Lubricants Market, with Brazil, Mexico, and Argentina leading regional adoption. Brazil’s automotive component industry, which produced over 2.6 million units in 2023, has significantly shifted toward water-based lubricants to align with national emissions targets. Mexican electronics and appliance manufacturers, concentrated around Guadalajara, are adopting oil-free solutions to meet export quality requirements, particularly for North American and European markets.

The adoption curve is being accelerated by foreign direct investments in high-tech manufacturing facilities, where international OEMs enforce strict standards for lubricant selection. As these facilities expand, Latin America’s share in the Oil Free Stamping Lubricants Market is expected to grow consistently, with a projected CAGR of 9.8% through 2029.

Market Segmentation by Product Type in the Oil Free Stamping Lubricants Market

The Oil Free Stamping Lubricants Market is segmented into water-based, synthetic, and biodegradable lubricants. Water-based lubricants currently hold the largest market share, accounting for nearly 47% of total consumption in 2024. These are widely used in general-purpose stamping due to their low cost, easy disposal, and strong cooling performance. For example, large-scale appliance manufacturers in China and Southeast Asia use water-based lubricants in high-speed presses to maintain clean surface finishes without post-process cleaning.

Synthetic oil-free lubricants, on the other hand, are gaining popularity in high-precision and heavy-load applications. These include aerospace parts, automotive body structures, and electrical enclosures. Synthetic formulations made from esters and advanced polymers offer extended die protection, reduced oxidation, and superior lubricity. In 2024, synthetic variants comprised 39% of the Oil Free Stamping Lubricants Market, with usage growing fastest in North America and Japan.

Biodegradable lubricants are expanding their footprint, especially in environmentally regulated industries. For instance, in the European Union, over 22% of stamping operations in the automotive sector now rely on biodegradable oil-free formulations. Their usage is being driven by the circular economy model and ESG compliance goals adopted by several OEMs and suppliers.

Segmentation by Application Reflecting Evolving End-User Needs in the Oil Free Stamping Lubricants Market

By application, the Oil Free Stamping Lubricants Market is segmented into metal forming, die casting, and other industrial stamping uses. Metal forming dominates the segment, accounting for over 68% of global lubricant demand. This includes deep drawing, bending, and blanking operations across automotive, HVAC, and white goods industries. In India, for instance, metal forming activities related to EV components have grown by 26% in volume from 2021 to 2024, directly increasing the use of oil-free stamping fluids.

Die casting applications, while a smaller segment, are highly value-intensive. In aerospace and heavy-duty automotive parts, the use of oil-free lubricants during die casting helps improve component finish, reduce porosity, and extend mold life. This segment is particularly strong in Italy, South Korea, and parts of North America.

Other applications include sectors such as packaging, textiles, and medical devices, where high purity and contamination-free production are essential. For example, medical-grade stainless steel components used in surgical instruments require oil-free lubricants that leave no residue and conform to cleanroom standards. These niche segments are becoming increasingly important contributors to the overall Oil Free Stamping Lubricants Market.

End-User Segmentation Highlighting Diverse Demand Patterns in the Oil Free Stamping Lubricants Market

In terms of end-users, the Oil Free Stamping Lubricants Market is segmented across automotive, electronics, aerospace, heavy machinery, and emerging sectors like medical devices and renewable energy. The automotive industry leads with 48% share, driven by mass production of body panels, powertrain parts, and structural components. The move toward aluminum and lightweight materials in vehicle design is further accelerating the need for high-efficiency oil-free lubricants.

Electronics manufacturing contributes nearly 18% to the market, driven by precision stamping of connectors, shielding plates, and enclosures. The miniaturization trend in electronics calls for oil-free lubricants that perform well at micro-scale tolerances. Aerospace follows closely, with nearly 12% share, focusing on safety-critical components made of titanium and nickel alloys where conventional lubricants fall short.

Heavy machinery accounts for 10%, primarily in construction and mining applications where die longevity and heat resistance are priorities. Emerging sectors such as solar panel framing and battery casings are also gaining relevance, pushing the Oil Free Stamping Lubricants Market into new industrial territories.

Leading Manufacturers Driving the Oil Free Stamping Lubricants Market Forward

The Oil Free Stamping Lubricants Market is shaped by a diverse mix of global and regional players, each contributing through product innovation, specialized formulations, and strategic expansion across high-demand sectors like automotive, aerospace, and electronics. These companies are not only producing high-performance lubricants but are also responding to shifting regulatory landscapes and sustainability goals with tailored product lines.

Quaker Houghton: Engineering Fluids for Sustainable Metal Forming

Quaker Houghton remains a dominant player in the Oil Free Stamping Lubricants Market, with its product series such as QUAKERDRAW and HOUGHTO-DRAW specifically developed for clean stamping operations. These oil-free formulations are designed to perform under high-speed conditions and are widely adopted across the automotive and appliance manufacturing sectors. For example, the QUAKERDRAW 420 Series includes water-based lubricants with rust inhibition and cooling capabilities that reduce post-processing requirements. The company has partnered with several EV manufacturers to provide clean stamping solutions compatible with lightweight aluminum components.

Fuchs Petrolub: Sustainable Product Portfolios for Global Industries

Germany-based Fuchs Petrolub offers a wide range of oil-free lubricants under its STABYL and ANTICORIT brands. The ANTICORIT DFO series is specifically formulated for stamping and forming operations requiring zero-oil residue and minimal friction. These lubricants are extensively used in the European automotive industry, especially in Germany and France, where high-speed progressive die stamping requires maximum die protection with minimum lubricant buildup. Fuchs is also advancing plant-based oil-free lubricants for manufacturers targeting EU environmental certifications.

Klüber Lubrication: Precision Lubricants for Aerospace and Electronics

A key innovator in the Oil Free Stamping Lubricants Market, Klüber Lubrication offers a range of specialty stamping lubricants tailored for electronics and aerospace applications. The Klüberform product line includes oil-free, synthetic stamping lubricants that provide excellent film strength, even under extreme forming pressure. Klüberform ST 4-701, for instance, is used in stamping precision connectors and electronic enclosures, especially in Japan and South Korea. These lubricants are prized for their high thermal stability and compatibility with sensitive metals such as copper and nickel alloys.

Castrol: High-Performance Oil Free Metalworking Fluids

Castrol, a division of BP, has positioned itself strongly in the Oil Free Stamping Lubricants Market through its Castrol Iloform series. The Iloform BWN range includes oil-free, water-based lubricants suitable for blanking and forming ferrous and non-ferrous metals. These products are widely used in UK and European manufacturing plants and are formulated to reduce die wear while minimizing the need for post-stamping cleaning. Castrol’s collaboration with aerospace and electronics OEMs to deliver cleanroom-compatible lubricants has further boosted its presence in the oil-free segment.

TotalEnergies: Biodegradable and Water-Based Formulation Pioneer

TotalEnergies has emerged as a leader in offering sustainable oil-free stamping solutions through its Finavestan and Lubrilog product lines. In France, where the company has a strong manufacturing base, TotalEnergies supplies water-based stamping lubricants used in EV battery casing production and other lightweight structural components. Their BioLife series, derived from vegetable-based esters, meets stringent biodegradability criteria, making them a preferred choice for customers pursuing circular economy goals.

Zschimmer & Schwarz: Customized Oil Free Lubricants for Niche Markets

Zschimmer & Schwarz specializes in tailor-made chemical solutions and has developed niche offerings in the Oil Free Stamping Lubricants Market. Their Metallform product range is engineered for stamping fine electronic components, such as heat sinks and battery connectors. These lubricants deliver ultra-low residue and reduce micro-deformation during high-precision stamping operations. The company has gained traction in the Southeast Asian market, particularly in Taiwan and Singapore, where electronics assembly is highly advanced.

PETRONAS Lubricants International: Advancing the Transition to Oil-Free Manufacturing

In Italy, PETRONAS has developed stamping lubricants designed for high-temperature applications in automotive and aerospace sectors. Their PETRONAS Syntium Industrial Fluids portfolio includes oil-free lubricants optimized for press forming operations requiring consistent lubrication under dynamic pressure. The company has recently expanded its production capabilities in Europe, responding to growing demand for sustainable manufacturing inputs.

Yushiro Chemical: Oil Free Expertise in Automotive and Electronics Manufacturing

Japan-based Yushiro Chemical is a specialist in metalworking fluids and a major supplier to automotive OEMs and electronics manufacturers across Asia. The Yushiro Forming 5000 Series includes oil-free, synthetic lubricants used extensively in precision stamping of automotive parts, electric motors, and compact metal casings. The company continues to invest in R&D, developing formulations with enhanced die-cooling and friction control, aligning with the increasing complexity of stamped components in electric mobility.

Nippon Oil Corporation: Innovation in High-Pressure Oil Free Stamping Lubricants

Nippon Oil has carved a niche in the Oil Free Stamping Lubricants Market with advanced solutions for heavy-duty forming operations. Their oil-free ENEOS Industrial Lubricants are designed to meet the rigorous demands of stamping large body panels and structural automotive parts. With significant penetration in the Asia Pacific region, Nippon Oil’s lubricants are valued for their thermal resistance, tool longevity, and environmental safety.

Recent Developments and Industry Trends in the Oil Free Stamping Lubricants Market

The Oil Free Stamping Lubricants Market has seen multiple product launches, expansions, and strategic moves in recent quarters. These developments signal a strong competitive landscape and a future-oriented industry focus:

- June 2023 – Quaker Houghton announced the expansion of its production facility in the U.S. to support increased demand from electric vehicle component manufacturers using oil-free metal forming lubricants.

- October 2023 – Fuchs Petrolub introduced a new biodegradable lubricant under the ANTICORIT DFO-Bio line, specifically targeting manufacturers transitioning to 100% oil-free production lines in Europe.

- January 2024 – Castrol launched Iloform ECO BWN 220, a new water-based lubricant with improved corrosion protection, developed for high-humidity manufacturing environments in Southeast Asia.

- March 2024 – Klüber Lubrication unveiled its Klüberform ST series 5, a new generation of oil-free lubricants certified for cleanroom-grade electronics manufacturing, meeting Class 1000 requirements.

- February 2024 – Yushiro Chemical expanded its facility in Thailand to triple output capacity for synthetic oil-free lubricants catering to Southeast Asia’s growing electronics assembly market.

- April 2024 – PETRONAS Lubricants launched a collaboration with an Italian aerospace firm to develop high-temperature oil-free lubricants for turbine component stamping.

These milestones underscore the momentum behind the Oil Free Stamping Lubricants Market and the strategic intent of key players to strengthen their portfolios around sustainability, precision performance, and regional customization.

Market Scenario, Demand vs Supply, Average Product Price, Import vs Export, till 2035

- Global Oil Free Stamping Lubricants Market revenue and demand by region

- Global Oil Free Stamping Lubricants Market production and sales volume

- United States Oil Free Stamping Lubricants Market revenue size and demand by country

- Europe Oil Free Stamping Lubricants Market revenue size and demand by country

- Asia Pacific Oil Free Stamping Lubricants Market revenue size and demand by country

- Middle East & Africa Oil Free Stamping Lubricants Market revenue size and demand by country

- Latin America Oil Free Stamping Lubricants Market revenue size and demand by

- Import-export scenario – United States, Europe, APAC, Latin America, Middle East & Africa

- Average product price – United States, Europe, APAC, Latin America, Middle East & Africa

- Market player analysis, competitive scenario, market share analysis

- Business opportunity analysis

Key questions answered in the Global Oil Free Stamping Lubricants Market Analysis Report:

- What is the market size for Oil Free Stamping Lubricants in United States, Europe, APAC, Middle East & Africa, Latin America?

- What is the yearly sales volume of Oil Free Stamping Lubricants and how is the demand rising?

- Who are the top market players by market share, in each product segment?

- Which is the fastest growing business/ product segment?

- What should be the business strategies and Go to Market strategies?

The report covers Oil Free Stamping Lubricants Market revenue, Production, Sales volume, by regions, (further split into countries):

- Asia Pacific (China, Japan, South Korea, India, Indonesia, Vietnam, Rest of APAC)

- Europe (UK, Germany, France, Italy, Spain, Benelux, Poland, Rest of Europe)

- North America (United States, Canada, Mexico)

- Latin America (Brazil, Argentina, Rest of Latin America)

- Middle East & Africa

Table of Contents:

Oil-Free Stamping Lubricants Market:

- Introduction to Oil-Free Stamping Lubricants

- Overview of Oil-Free Stamping Lubricants and Their Role in Manufacturing

- Types of Oil-Free Stamping Lubricants: Water-Based, Synthetic, and Semi-Synthetic

- Benefits of Oil-Free Formulations in the Stamping Process

- Market Overview and Trends

- Global Oil-Free Stamping Lubricants Market Size and Growth Prospects

- Key Market Drivers: Environmental Regulations, Sustainability, and Cost Efficiency

- Challenges in the Market: Performance Trade-offs and Adoption Barriers

- Market Dynamics

- Factors Driving Demand for Oil-Free Stamping Lubricants

- Technological Advancements and Innovations in Lubricant Formulation

- Impact of Industry 4.0 and Automation on Lubricant Demand

- Oil-Free Stamping Lubricants by Application

- Automotive Industry: Usage in Sheet Metal Forming and Stamping Processes

- Aerospace and Defense: Precision and High-Performance Applications

- Consumer Electronics and Electrical Equipment

- Industrial Equipment Manufacturing and Metal Processing

- Market Segmentation

- By Product Type: Water-Based, Synthetic, and Semi-Synthetic Lubricants

- By Application: Automotive, Aerospace, Electronics, and Industrial Manufacturing

- By End-Use: OEMs, Aftermarket, and Service Providers

- Performance Characteristics of Oil-Free Stamping Lubricants

- Comparison of Performance: Lubrication Efficiency, Wear Protection, and Surface Finish Quality

- The Role of Lubricant Viscosity and Additives in Process Optimization

- How Oil-Free Lubricants Enhance Sustainability Without Compromising Performance

- Environmental Impact and Sustainability

- Environmental Regulations Influencing the Adoption of Oil-Free Stamping Lubricants

- The Role of Biodegradable and Eco-Friendly Formulations

- Waste Management and Disposal of Oil-Free Lubricants

- Technological Innovations in Oil-Free Stamping Lubricants

- Development of Advanced Additives and Their Impact on Lubricant Performance

- Innovations in High-Pressure and Extreme Temperature Conditions

- Use of Nano-Technology in Improving Lubricant Effectiveness

- Competitive Landscape

- Leading Companies in the Oil-Free Stamping Lubricants Market: Profiles and Strategies

- Market Share Analysis of Key Players in the Global Market

- Strategic Collaborations, Mergers, and Acquisitions in the Oil-Free Lubricants Sector

- Pricing Trends and Cost Structure

- Factors Affecting Pricing of Oil-Free Stamping Lubricants

- Cost Comparison: Traditional Oil-Based vs. Oil-Free Stamping Lubricants

- Price Sensitivity in the Automotive and Heavy Industries

- Oil-Free Stamping Lubricants Market by Region

- North America: Market Trends, Key Players, and Consumer Demand

- Europe: Regulatory Landscape and Sustainability Focus

- Asia Pacific: Rapid Industrialization and Demand Growth in Manufacturing

- Latin America: Market Development and Opportunities in Emerging Economies

- Middle East & Africa: Growth in Metalworking and Manufacturing Sectors

- Consumer Insights and Demand Forecast

- Consumer Preferences in Selecting Oil-Free Stamping Lubricants

- Adoption Barriers: Technical, Cost, and Knowledge Gaps

- Growth Projections for the Next Decade and Market Opportunities

- Raw Materials and Supply Chain Analysis

- Key Raw Materials Used in the Production of Oil-Free Stamping Lubricants

- Supply Chain Challenges: Sourcing, Logistics, and Cost Implications

- Impact of Global Trade Dynamics on Raw Material Availability

- Regulatory and Compliance Landscape

- Overview of Environmental Regulations Governing Stamping Lubricants

- Health and Safety Standards in Manufacturing and Use of Oil-Free Lubricants

- Regional Compliance Requirements and Their Impact on the Market

- Impact of COVID-19 on the Oil-Free Stamping Lubricants Market

- Market Disruptions and Supply Chain Challenges during the Pandemic

- Changes in Manufacturing Demand and Shifts in Consumer Behavior

- Recovery Strategies and Future Market Outlook

- Challenges in the Oil-Free Stamping Lubricants Market

- Technical Limitations in High-Performance Applications

- Compatibility Issues with Existing Manufacturing Equipment

- Overcoming Resistance to New Technology and Product Adoption

- Future Trends and Opportunities

- The Rise of Customizable and Tailored Oil-Free Lubricant Solutions

- Potential for Expanding Applications in Emerging Industries (Electric Vehicles, Renewable Energy)

- The Future of Green Chemistry and Sustainable Solutions in Lubricant Development

- Market Forecast and Projections

- Oil-Free Stamping Lubricants Market Forecast (2025-2035)

- Projected Market Size and Growth Rate by Region and Product Type

- Emerging Market Segments and Future Opportunities

- Strategic Recommendations

- Recommendations for Manufacturers to Drive Market Penetration and Growth

- Key Areas for Innovation and Product Development

- Investment Opportunities in the Oil-Free Stamping Lubricants Market

- Conclusion

- Summary of Key Insights and Market Outlook

- Strategic Direction for Stakeholders and Industry Participants

- Long-Term Impact of Oil-Free Solutions on the Metalworking Industry

Other recently published reports:

“Every Organization is different and so are their requirements”- Datavagyanik

Companies We Work With

Do You Want To Boost Your Business?

drop us a line and keep in touch